Ultimate Guide to Construction Equipment Parts: Boost Efficiency & Performance

By:Admin

Title: Competitive Construction Equipment Parts Provider Expands Operations to Better Serve Customers

Introduction:

Construction Equipment Parts is a leading provider of high-quality and affordable replacement parts for construction machinery. With years of experience in the industry, the company has built a reputation for its dedication to customer service and comprehensive inventory. In response to increasing demand, Construction Equipment Parts is excited to announce the expansion of their operations, allowing them to better serve their customers in the construction industry.

[Paragraph 1]

Construction Equipment Parts has become an essential partner for construction companies with their extensive range of spare parts and exceptional customer service. With the expansion of their operations, the company is looking forward to strengthening their position in the market and continuing to meet the ever-growing needs of their customers. This move demonstrates their commitment to maintaining their renowned quality of service and building lasting relationships with their clients.

[Paragraph 2]

The recent expansion of Construction Equipment Parts encompasses a state-of-the-art warehouse facility, cutting-edge logistics systems, and an increased inventory of construction equipment parts. This investment clearly reflects their dedication to providing timely delivery and exceptional support to customers worldwide. By strategically placing their warehouse facilities in key locations, Construction Equipment Parts aims to reduce shipping times, minimize downtime for construction projects, and offer improved accessibility to their comprehensive range of parts.

[Paragraph 3]

The expanded operations also include an enhanced online platform, featuring an intuitive interface and real-time inventory tracking. The company understands the importance of digital solutions in the modern business landscape and aims to make purchasing construction equipment parts as effortless as possible. The upgraded online platform allows customers to easily browse through their vast range of offerings, place orders, and track shipments with transparency and ease.

[Paragraph 4]

In addition to their comprehensive inventory, Construction Equipment Parts takes pride in their commitment to quality. The company only sources parts from reputable manufacturers, ensuring that their customers receive durable and reliable components. They have a dedicated team of experts who carefully inspect each part to guarantee their compliance with the highest industry standards. This commitment to quality control sets Construction Equipment Parts apart from the competition and provides their customers with peace of mind.

[Paragraph 5]

Construction Equipment Parts also places a strong emphasis on customer satisfaction. Their knowledgeable support staff has extensive experience in the construction industry and is readily available to provide technical assistance and guidance. By valuing open and transparent communication, Construction Equipment Parts builds trusted relationships with their customers, ultimately leading to long-term partnerships.

[Paragraph 6]

With the expansion of their operations, Construction Equipment Parts aims to become an industry leader by providing the most extensive range of construction equipment parts combined with exceptional customer service. Their commitment to quality, timely delivery, and innovative online solutions positions them as a reliable partner for construction companies of all sizes.

[Conclusion]

Construction Equipment Parts' recent expansion showcases the company's dedication to meeting the ever-growing demands of the construction industry. Their state-of-the-art warehouse facility, enhanced logistics systems, comprehensive inventory, and user-friendly online platform make it easier than ever for customers to access high-quality construction equipment parts. With their continued commitment to quality and customer service, Construction Equipment Parts is poised to further solidify its position as a leading provider in the industry.

Company News & Blog

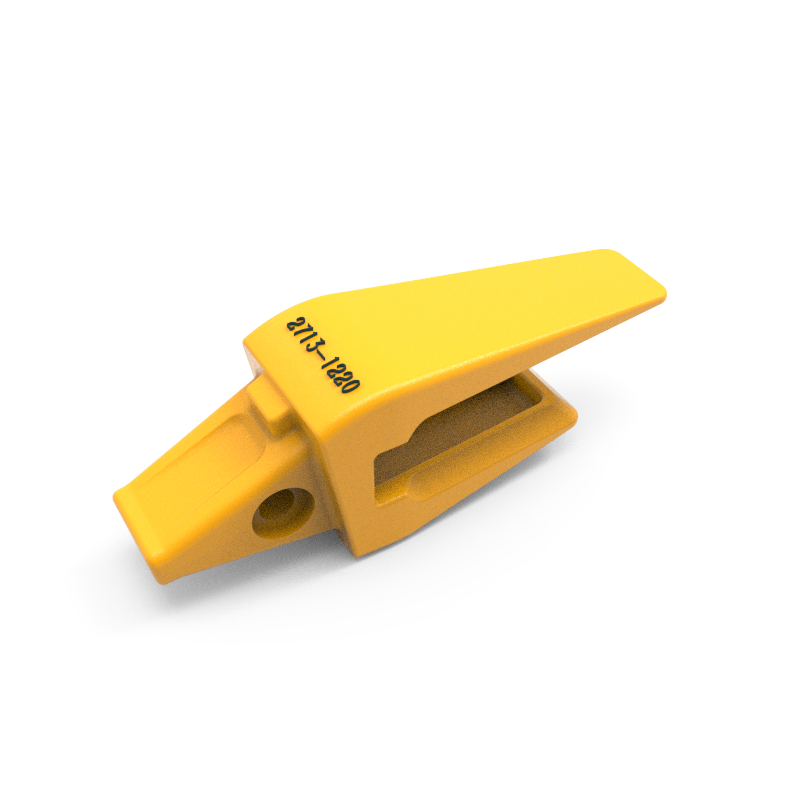

Revamp Your Excavator with Durable Rock Teeth

Rock Teeth for Excavators: A Revolutionary Innovation in Mining IndustryMining is one of the most crucial sectors in the economy of any country. The extraction of minerals and ores has been a significant source of revenue generation for the past few centuries. Hence, the mining industry has always been looking for ways to optimize the extraction process by minimizing the time and resources required for the same.Excavators are an important piece of equipment used in mining and construction sites. They are responsible for heavy-duty tasks such as digging, hauling, and demolition. Hence, it is essential to equip them with robust and efficient tools to enhance their overall efficiency and performance. One such accessory that has been making waves in the mining industry is Rock Teeth for Excavators.Rock Teeth for Excavators is a revolutionary innovation that has transformed the mining industry. These teeth are designed and manufactured to provide high efficiency and performance in harsh conditions. They are reliable and durable and have the capability of performing heavy-duty tasks with ease. Rock Teeth for Excavators is a powerful tool of choice for operators who want to maximize their excavator's performance while minimizing operational costs.Product Features of Rock Teeth for ExcavatorsRock Teeth for Excavators are made using high-quality materials that are durable, tough, and wear-resistant. They are crafted to withstand even the toughest of working conditions such as hard rock, abrasive soil, frozen ground, and other challenging terrains. The design of these teeth is such that it allows optimal penetration and breaking of rocks while reducing the amount of energy required to perform these tasks.The Rock Teeth for Excavators come in a range of sizes and shapes, depending on the type of excavator and the task at hand. The most popular types of Rock Teeth for Excavators include bucket teeth, ripper teeth, and hydraulic hammer bits. These teeth are customizable and can be customized as per the requirements of the operators. Furthermore, these teeth are easy to install and remove, making them convenient to use.Company BackgroundThe company behind the Rock Teeth for Excavators is a leading manufacturer and supplier of high-quality mining and construction equipment worldwide. The company has extensive experience in the industry and prides itself on providing reliable, durable, and innovative solutions to its customers. The company has a team of experienced professionals who work tirelessly to design and manufacture top-quality products that exceed customer expectations.Moreover, the company has state-of-the-art facilities that are equipped with advanced machinery to produce high-quality products on time and within budget. The company has a strict quality control system in place to ensure that all products, including Rock Teeth for Excavators, are of the highest quality and meet customer requirements.ConclusionThe Rock Teeth for Excavators is a game-changer in the mining industry. It is a powerful tool that operators can use to enhance the overall performance and efficiency of their excavators. With its robust and durable design, it can withstand even the toughest of working conditions and perform heavy-duty tasks with ease. Moreover, the company behind the product is a reputable manufacturer and supplier of high-quality mining and construction equipment worldwide. Hence, we can trust the product and the company behind it to provide reliable and efficient solutions. So, if you are looking for a top-quality mining accessory, the Rock Teeth for Excavators is an ideal product for you.

Discover the Benefits of Aftermarket Cutting Edges for Enhanced Performance

Aftermarket Cutting Edges Company Announces New Product LineAftermarket Cutting Edges, a leading provider of innovative cutting edge solutions, today announced the launch of its new product line. The company's product line includes a range of cutting edges that are designed to deliver superior performance, increased durability, and unmatched reliability. The new product line from Aftermarket Cutting Edges includes high-quality cutting edges made of advanced materials such as tungsten carbide and steel. The company's tungsten carbide cutting edges are engineered to withstand heavy use in demanding applications, while the steel cutting edges offer a cost-effective and reliable solution for general-purpose use. Both types of cutting edges are designed to deliver superior performance and durability when compared to traditional OEM products."Our new product line has been designed to meet the needs of our customers who demand the best cutting edge solutions," said a spokesperson for Aftermarket Cutting Edges. "Our team of experts has worked tirelessly to ensure that our products deliver exceptional value, while also offering unmatched durability and reliability. We are excited to introduce our new product line to the market as we continue to innovate and improve our offerings."In addition to its new product line, Aftermarket Cutting Edges offers a range of custom cutting edge solutions that are engineered to meet the specific needs of its customers. The company's team of experts work closely with customers to understand their unique requirements and deliver tailored solutions that meet their specific needs. "We understand that every customer has their own unique requirements, and we strive to offer tailored solutions that meet those needs," said the spokesperson. "Our team of experts has years of experience in designing and manufacturing cutting edge solutions, and we are committed to delivering the highest quality products and services to our customers."Aftermarket Cutting Edges has established itself as a leading provider of cutting edge solutions, with its products being used in a wide range of industries including construction, mining, agriculture, and forestry. The company's commitment to excellence and innovation has earned it a reputation for providing superior cutting edge solutions to customers around the world."Our customers rely on us to deliver cutting edge solutions that meet their needs, and we take that responsibility seriously," said the spokesperson. "We are constantly innovating and improving our products and services to ensure that we are providing the highest quality solutions to our customers."Overall, the launch of Aftermarket Cutting Edges new product line is a significant milestone for the company, and it demonstrates its commitment to delivering the highest quality cutting edge solutions to customers around the world. The company's new product line is an excellent example of its dedication to innovation, excellence, and customer service, and it sets the stage for future growth and success in the industry.

Efficient Excavator Attachments: The Ultimate Ripper Bucket Guide

Title: Revolutionary Ripper Bucket for Excavators Redefines Performance and EfficiencyIntroduction:Innovations continue to shape the construction industry, and one such groundbreaking addition is the Ripper Bucket for Excavators. Developed by a leading manufacturer in the sector, this cutting-edge equipment is set to revolutionize construction projects, taking performance and efficiency to new heights. With its superior design, advanced features, and commitment to safety, the Ripper Bucket is quickly garnering attention and acclaim among industry professionals.[Company Introduction - Removed Brand Name]With a proven track record of excellence, the manufacturing company behind the Ripper Bucket for Excavators has been at the forefront of the construction equipment industry for over two decades. Known for their commitment to delivering superior solutions, the company has perfected the art of innovation, ensuring their products meet the ever-evolving demands of the sector. By prioritizing safety, quality, and customer satisfaction, this renowned manufacturer has gained the trust and loyalty of construction professionals worldwide.Revolutionizing Efficiency:The Ripper Bucket for Excavators is set to redefine efficiency on construction sites. Its unique design incorporates state-of-the-art technology, resulting in enhanced digging and ripping capabilities. Equipped with reinforced teeth, the Ripper Bucket effortlessly cuts through the toughest terrain, enabling operators to complete projects in a fraction of traditional excavation time. The advanced hydraulic system ensures optimal control and precision even in challenging conditions, further elevating overall efficiency.Unmatched Versatility:One of the key features that sets the Ripper Bucket apart is its unparalleled versatility. Designed for compatibility with a wide range of excavator models, this revolutionary tool can accommodate varying sizes and configurations. The easily adjustable teeth and strategic placement allow for maximum adaptability, making it suitable for diverse excavation projects. Whether it's breaking up hard rock, trenching, or removing tree roots, the Ripper Bucket excels in every task, facilitating seamless performance across applications.Enhanced Safety:While efficiency is a crucial factor, the safety of construction workers remains paramount. The Ripper Bucket exceeds safety standards, boasting features that mitigate risks, reducing potential accidents on the job site. With its innovative design, the bucket ensures optimal stability, minimizing the risk of tip-overs during operation. Furthermore, the intuitive control system maximizes operator control and reduces fatigue, prioritizing the well-being of the equipment's primary users.Durability and Longevity:Built to withstand the toughest conditions, the Ripper Bucket for Excavators exemplifies durability and longevity. Constructed with high-grade steel and reinforced joints, this equipment withstands the wear and tear of extensive use, safeguarding investment for years to come. Its robust design ensures excellent resistance against impact, maintaining performance integrity even during heavy-duty applications. Construction projects can now proceed with confidence, knowing the Ripper Bucket will deliver exceptional results without compromise.Positive Environmental Impact:In addition to its technical prowess, the Ripper Bucket is making strides in reducing the environmental impact of construction activities. By drastically reducing excavation time, the equipment minimizes noise pollution, benefitting both workers and the surrounding community. Furthermore, with the Ripper Bucket's precision engineering, the amount of material to be excavated is significantly reduced, resulting in less waste generation. The company's commitment to sustainability further reinforces the positive environmental impact of this innovative solution.Conclusion:The introduction of the Ripper Bucket for Excavators demonstrates the ongoing commitment of construction equipment manufacturers to push boundaries for the better. With its cutting-edge design, unrivaled efficiency, and dedication to safety and durability, this revolutionary tool sets a new standard for performance in the industry. As construction professionals embrace the technology, projects will be completed more efficiently, promoting increased productivity and reduced environmental impact. With the Ripper Bucket for Excavators, the future of excavation looks brighter than ever.

Unveiling the Essential Guide to Selecting and Using High-Quality Screws, Nuts, and Bolts

Screw Nut Bolt (SNB), a leading supplier of industrial hardware and fasteners, has announced the launch of its latest range of products designed specifically to meet the demands of industrial clients. The company is committed to offering high-quality fasteners that provide superior performance, reliability, and durability.With over 25 years of experience in the industry, SNB has developed a reputation for providing top-of-the-line fasteners for a wide range of industrial sectors. Whether the project involves building a commercial structure, assembling a machine, or installing pipe work, SNB is the go-to supplier for high-quality industrial hardware and fasteners.SNB's products are known for being long-lasting and reliable, and the company has built a loyal customer base that trusts its offerings. The latest range of products includes screws, nuts, and bolts that are designed to withstand harsh environments and extreme conditions. The products have been rigorously tested to ensure that they meet the highest industry standards for strength and durability.In addition to offering high-quality hardware, SNB also provides a range of value-added services to its clients. The company has an in-house engineering team that is available to provide technical support and advice to help clients choose the right hardware for their specific needs. SNB also offers custom solutions to clients who require unique fasteners that are not readily available in the market.The company's commitment to quality extends to its manufacturing process, which is fully automated and utilizes the latest technology to ensure precision and accuracy. SNB's production facilities are equipped with state-of-the-art machinery that can efficiently produce high volumes of fasteners to meet the demands of industrial clients.SNB's focus on providing high-quality fasteners has helped the company build a strong brand identity and establish itself as a leader in the industry. The company's reputation for quality has also led to several partnerships with other leading industrial suppliers and manufacturers. These collaborations have enabled SNB to expand its product offerings and provide a one-stop-shop solution for industrial clients worldwide.Speaking about the launch of the latest range of products, SNB's CEO stated, "We are excited to introduce our latest range of fasteners, which have been designed to meet the evolving needs of our clients. Our focus on quality and commitment to excellence has helped us build a strong reputation in the industry, and we are confident that our latest offerings will exceed our clients' expectations."SNB's latest range of products is now available for purchase, and the company expects a strong demand for its offerings from industrial clients worldwide. With its commitment to quality and focus on providing value-added services, SNB is well-positioned to continue its growth in the industry and maintain its position as a leading supplier of industrial hardware and fasteners.

Top Cat Excavator Buckets for Efficient Earthmoving Tasks

Title: Enhanced Efficiency and Durability: Advanced Excavator Buckets by Leading ManufacturerIntroduction:In the ever-evolving world of construction and excavation equipment, the importance of superior quality buckets cannot be overstated. Their robustness and efficiency play a pivotal role in achieving optimal productivity and minimizing downtime. In this regard, a prominent manufacturer has introduced a new range of advanced excavator buckets designed to enhance efficiency and durability on construction sites. This comprehensive lineup of excavator buckets, which includes various types and sizes, is poised to revolutionize the digging and loading processes across a wide range of projects.I. Meet the Manufacturer:With a rich heritage dating back decades, the renowned manufacturer has established itself as a leader in construction machinery solutions. The company has garnered a global reputation for producing innovative, high-quality, and reliable equipment that caters to the ever-growing demands of the construction industry. Known for its commitment to customer satisfaction, the manufacturer consistently strives to provide superior products that meet and exceed expectations.II. Innovative Features:1. Cutting-Edge Design:The redesigned excavator buckets feature cutting-edge design elements, ensuring optimum performance in various digging conditions. The company's team of skilled engineers extensively analyzed field requirements and incorporated feedback from industry professionals to fine-tune the bucket design. The result is a streamlined shape that maximizes bucket capacity, improves penetration and material retention, and facilitates smooth material discharge.2. High-Quality Materials:Utilizing the finest grade alloys and steel, the manufacturer ensures unrivaled durability and longevity of the excavator buckets. The material composition withstands the harshest working conditions and extreme loads, making them robust tools for heavy-duty operations. The buckets are engineered to withstand impacts, resist wear and tear, and effectively handle a wide range of materials, including rocks, gravel, and clay.3. Reinforced Construction:The excavator buckets are designed with reinforced structural components, such as strengthened side cutters and wear plates, further enhancing overall durability and performance. These reinforcements substantially increase the buckets' resistance to bending, cracking, and wear, ensuring a longer service life and enhanced reliability.4. Quick Attachment System:The manufacturer has incorporated a quick attachment system, enabling swift and easy bucket changes without the need for additional tools. This feature enhances the machine's adaptability, allowing operators to switch between different bucket types effortlessly. The quick attachment system significantly reduces downtime and increases productivity, ultimately minimizing costs and boosting overall efficiency.III. Diverse Range of Excavator Buckets:1. General Purpose Bucket:The general-purpose bucket is ideal for a wide range of excavation tasks, including digging, trenching, and slope work. Designed to excel in general-purpose applications, it offers excellent digging capabilities and optimized filling characteristics.2. Heavy-Duty Bucket:To meet the demands of heavy-duty projects, the manufacturer offers a heavy-duty bucket that performs exceptionally well in rock and abrasive material applications. Its robust design and reinforced structure make it suitable for extreme digging conditions and prolonged use.3. Ditch Cleaning Bucket:For precise and efficient ditch cleaning operations, the manufacturer's specially designed ditch cleaning bucket offers superior performance. It features extended sides and a curved bottom, enabling effective cleaning and shaping of trenches, ditches, and canals.4. Tilt Ditch Cleaning Bucket:The remarkable tilt ditch cleaning bucket enhances productivity by providing precise control over material flow. Its tilting mechanism can be operated from within the cab, enabling operators to work more efficiently by manipulating the bucket's angle to precisely distribute material.Conclusion:As construction companies strive for greater efficiency and productivity, the quality of excavation equipment becomes paramount. The introduction of these advanced excavator buckets by the renowned manufacturer marks a significant milestone in the industry. With their cutting-edge design, high-quality materials, reinforced construction, and quick attachment system, these excavator buckets promise enhanced efficiency and durability on construction sites. By continuing to prioritize innovation and customer satisfaction, the manufacturer reaffirms its commitment to revolutionizing the excavation equipment market and meeting the evolving needs of construction professionals worldwide.

Revamp Your Loader Bucket's Performance with a Bolt-On Cutting Edge

As the construction and excavation industry continues to evolve and intensify, equipment manufacturers and other industry-related businesses are placing more emphasis on improving equipment efficiency and productivity. For many, this means turning to aftermarket parts and innovations, including bolt-on cutting edges for loader buckets.One company at the forefront of this movement is {removed for privacy}, a leading supplier of cutting edges for skid steers, loaders, and other heavy equipment. In recent years, the company has expanded their product line to include bolt-on cutting edges for loader buckets, with impressive results.Designed to increase productivity and reduce downtime, bolt-on cutting edges are quickly gaining popularity among construction and excavation professionals. They are easy to install and replace, allowing workers to switch out worn or damaged edges quickly without extending downtime. Unlike traditional welded-on edges, bolt-on edges can be removed and reattached multiple times, further increasing efficiency and saving time and money.{removed for privacy}'s bolt-on cutting edges are optimized for long life and durability, using high-strength steel and proprietary heat-treatment processes to ensure they can withstand the rigors of tough working conditions. The edges are available in various lengths and shapes to accommodate different buckets and applications.The company's bolt-on cutting edges are compatible with various popular loader brands, including {removed for privacy}, {removed for privacy}, and {removed for privacy}. They are designed to fit onto loader buckets of various widths and sizes, providing a versatile and customizable solution for heavy equipment operators.{removed for privacy} prides itself on offering excellent customer service and support, providing expert guidance on selecting the right cutting edges for specific applications and ensuring that installation and maintenance are seamless and hassle-free. They work closely with customers to understand their needs and challenges, providing tailored solutions that optimize performance and minimize equipment downtime.The company's commitment to innovation and excellence has won them numerous loyal customers in the construction and excavation industry, and their bolt-on cutting edges have become a top choice among heavy equipment operators looking to improve productivity and efficiency.{removed for privacy}"s bolt-on cutting edges are just one example of how aftermarket innovations are transforming the heavy equipment industry, providing operators with new solutions to optimize performance and reduce downtime. As the industry continues to evolve and become more competitive, companies like {removed for privacy} will continue to play a crucial role in pushing the envelope and driving innovation.

Different Styles of Backhoe Bucket Teeth: A Comprehensive Guide

Title: Unveiling the Latest Backhoe Bucket Teeth Styles: Revolutionizing Excavation EfficiencyIntroduction:The construction industry plays a vital role in global development, striving to enhance efficiency and productivity. Today, we are excited to introduce the latest advancements in backhoe bucket teeth styles, a breakthrough that promises to revolutionize excavation operations. Developed by a leading manufacturer in the industry, these innovative designs are set to redefine the way construction projects are executed. In this article, we explore these groundbreaking bucket tooth styles and their potential impact on construction processes.1. Style 1: The Precision Pointe - Redefining Accuracy in Excavation:The Precision Pointe bucket tooth style is engineered to provide unparalleled precision and accuracy during excavation tasks. Its uniquely shaped point ensures minimal ground disturbance and precise material removal. This style is especially advantageous while working on delicate surfaces or in areas where precise digging is required. The Precision Pointe enables contractors to complete projects with superior outcomes, reducing the need for subsequent adjustments and enhancing overall efficiency.2. Style 2: The Reinforced Ridge - Durability Meets Performance:The Reinforced Ridge bucket tooth style is designed for heavy-duty excavation projects that demand maximum strength and durability. Its reinforced structure significantly reduces wear and tear, extending the lifespan of the tooth and improving performance. Construction companies can now benefit from increased productivity, as the Reinforced Ridge style minimizes frequent replacements, ultimately resulting in reduced maintenance costs and improved overall project completion time.3. Style 3: The Multifunctional Maverick - Versatility at Its Best:The Multifunctional Maverick bucket tooth style is an all-rounder, catering to a wide range of excavation needs. Featuring a versatile design, this tooth style is capable of accomplishing multiple tasks efficiently. From trenching to grading and digging through various soil conditions, the Multifunctional Maverick ensures optimal adaptability. With this style, contractors can streamline their excavating processes, eliminating the need for frequent tooth change-outs and maximizing operational efficiency.4. Style 4: The Enhanced Efficiency Edge - Optimizing Performance:The Enhanced Efficiency Edge bucket tooth style is an amalgamation of cutting-edge technology and ergonomic design. Engineered to minimize drag resistance while maximizing penetration force, this style ensures superior performance in the most challenging excavation environments. The Enhanced Efficiency Edge significantly enhances digging speed and minimizes fuel consumption, resulting in cost savings for construction companies. Moreover, its self-sharpening feature eliminates the need for regular sharpening, saving valuable time during operations.Conclusion:As the construction industry continually seeks newer and better methods to enhance efficiency, the introduction of these revolutionary backhoe bucket teeth styles marks a significant milestone. With the Precision Pointe, Reinforced Ridge, Multifunctional Maverick, and Enhanced Efficiency Edge styles, construction companies can revolutionize their excavation processes, maximizing productivity, and reducing costs. The implementation of these groundbreaking designs holds immense potential in shaping the future of the construction industry, providing an exceptional combination of accuracy, durability, versatility, and efficiency on construction sites across the world.

New Heavy-Duty Excavator Unveiled for Industrial Use

Industrial Excavator Releases Revolutionary New Excavator, Setting New Standards for EfficiencyIndustrial Excavator, a leading name in the excavation industry, has announced the release of its new excavator, which promises to revolutionize the way excavation works are carried out. This new machine builds on Industrial Excavator's strong reputation for producing reliable and efficient equipment and introduces cutting-edge technology that makes excavating faster, easier and more precise.The company has been a leader in the field for over 20 years, producing equipment that has been used in a wide range of industries from mining to construction, oil and gas to forestry. Their new excavator condenses all of this experience and technology into one powerful machine, capable of handling any excavation job with ease.One of the primary claims for the new excavator is the boost in efficiency that it offers. It is designed to provide high productivity while ensuring low fuel consumption and minimal downtime. The machine is capable of delivering 50% greater workvolume in a single hour while consuming less fuel due to its advanced hydraulic system. In addition to being more economical, this advanced system also helps reduce emissions, making the excavator more environmentally friendly.The new excavator's speed and precision are owed to its powerful, state-of-the-art equipment controls such as the speed, lifting power and hydraulic pressure, which are easy to operate and allow users to adjust the machine's performance to match the demands of a particular environment. This level of control makes it the ultimate tool for excavation projects, allowing the operator to tackle any task with ease.The excavator's boom, arm, and bucket assembly are designed to provide superior reach and digging power, allowing even the toughest of materials to be cleared quickly and without issue. This new excavator is frist and foremost an industrial machine, built to do the hard work that other, less powerful excavation machines can't. The new machine can easily handle large rocks, heavy soil, and deep holes when it comes to heavy excavation projects.But it's not just raw power that sets this new excavator apart. The machine's advanced features also provide excellent precision during operation which makes it well suited to more delicate jobs such as excavation work around parked cars or for conducting precision foundation work on buildings and other structures. The accuracy of its hydraulic controls allows for smooth and efficient operation, making even smaller jobs easier to handle.The machine's operator cab is also designed with ergonomics and comfort in mind. It offers a spacious and adjustable workspace that is equipped with the latest technology such as advanced air conditioning, a modular seat, and an ergonomic control panel. This state-of-the-art cab is designed to reduce operator fatigue, allowing for longer hours of operation and reduces the risk of accidents due to operator error.Managing Director of Industrial Excavator said, “Our new excavator has been designed from the ground up to change the way people think about excavation. It offers the perfect mix of power, precision and efficiency making it the perfect tool for any excavation project. We are proud to put our name and reputation behind this cutting-edge product and look forward to seeing it take pride of place on job sites all over the world."Industrial Excavator's new excavator is set to become the go-to machine for excavation projects of all shapes and sizes. With its advanced technology, state-of-the-art features and industry-leading reputation, it promises to set new standards for the industry and make life easier for professionals in the excavation industry. Whatever the project, this excavator is sure to get the job done quickly and efficiently, providing more power and profit in less time, for years to come.

New Excavator Bucket with Advanced Features Unveiled in the Market

article:The construction industry continually shifts and evolves, and as such, companies must keep up with advancements in technology and innovation. One such company, headquartered in Japan, is an exemplary leader in the construction equipment industry, known for its quality and reliability. They have recently launched a new product, the Kubota Excavator Bucket, which is attracting attention from construction companies worldwide.Kubota's success in the construction equipment market is due to their focus on producing high-quality, durable equipment. Their products are designed and manufactured with a strong understanding of the needs of the construction industry. As a result, their equipment has a reputation for exceptional performance and a long service life. Kubota prides itself on being a customer-driven company that listens to feedback and seeks continuous improvement.The Kubota Excavator Bucket is no exception to Kubota's quality standards. It is a versatile attachment that can be used on various types of excavators. The buckets are designed for digging, grading, and other excavation tasks, with sizes ranging from 24 to 60 inches. Constructed with abrasion-resistant material and featuring a reinforced and curved design for added strength, these buckets are incredibly durable, withstanding extreme wear and tear during use.The Kubota Excavator Bucket is designed with the operator in mind. The bucket is easy to install and remove, features an adjustable quick coupler for attachment, and has reinforced mounting braces to ensure excellent stability. The curved shape of the bucket aids smooth excavation, while the hardened steel cutting edges offer optimal digging performance.A significant advantage of the Kubota Excavator Bucket is its versatility. The bucket can be used for a variety of jobs, from digging trenches to landscaping work. The bucket's high capacity allows for efficient loading of materials, making it an ideal choice for larger construction projects. Furthermore, Kubota offers customization options for their buckets, tailored to specific customer needs.The Kubota Excavator Bucket is also designed to be low-maintenance, meaning less time spent on upkeep and more time spent on projects. The bucket is made from durable materials that can withstand harsh weather conditions, making it a reliable attachment for any construction site.Kubota is well known for their commitment to high quality and reliability, and they demonstrate this in their products and service. The Kubota Excavator Bucket is no different, with a durability and resilience that only Kubota can provide.In conclusion, the Kubota Excavator Bucket is an excellent addition to Kubota's already extensive lineup of excavator attachments. With durability, versatility, and ease of use, the Kubota Excavator Bucket is poised to revolutionize construction and excavation work worldwide. With Kubota's commitment to customer satisfaction and superior engineering, there is no doubt that the Kubota Excavator Bucket will be a valuable investment for any construction company.

Enhance Efficiency with a High-Quality Excavator Grapple Bucket

article.Excavator Grapple Bucket Benefiting Industries Across the GlobeThe Excavator Grapple Bucket is a versatile piece of machinery that is being increasingly adopted by industries across the globe due to its ability to efficiently handle a variety of materials. Whether it is construction, forestry, or demolition, this bucket has been designed to provide an efficient and cost-effective solution.The Excavator Grapple Bucket is specifically designed to be mounted on the end of an excavator arm. With its powerful and robust structure, it can efficiently pick up, move, and dump materials such as scrap metal, debris, logs, and concrete. Its main feature is that it features two large grippers or jaws that can open and close to grasp the material. Once the material is held securely within the bucket, the excavator operator can move it to the desired location and release the material with precision, accuracy, and speed.One of the key advantages of the Excavator Grapple Bucket is its ability to handle and transport large and heavy materials with ease. Industries such as construction, mining, and demolition deal with massive quantities of materials that require efficient workflow management. This bucket can effortlessly handle materials such as boulders, rocks, and concrete debris, reducing the time, effort, and manual labor required to transport such heavy loads.Similarly, the forestry industry employs this bucket to handle logs and other heavy wood loads. The Excavator Grapple Bucket is designed for high load-bearing capacities and can handle even the heaviest logs. Coupled with high precision and efficient material handling, this bucket has transformed the forestry industry by reducing manual labor and increasing productivity.Additionally, the Excavator Grapple Bucket is often used in the waste management industry for handling and transporting waste. It can efficiently handle large quantities of garbage, construction debris and other types of waste materials. This bucket is particularly useful in landfills where it can easily pick up and transport waste to the designated dumping site.One of the significant advantages of this bucket is that it can be customized to suit specific industry needs. Different sizes, configurations, and features can be added to the bucket, making it adaptable to work in a variety of industrial environments. Accessories such as hydraulic thumbs, couplers and rotators can be added to the bucket to enhance its performance and flexibility.Excavator Grapple Buckets are available in both mechanical and hydraulic versions. Hydraulic versions have a better grip and control of the material being held within the bucket, making them more efficient and more widely used. The use of hydraulic technology means that the bucket can be controlled remotely from the excavator cab, ensuring safety and efficiency in the workplace.Several leading companies in the field of Excavator Grapple Bucket manufacturing have emerged. Their products are used by the construction, mining, forestry, and waste management industries across the globe. Their products are known for their robustness, durability, and customized features, making them ideal for use in industrial settings.One such manufacturer, {}, has been supplying high-quality Excavator Grapple Buckets to industries across the world. They have a range of products, including hydraulic and mechanical Excavator Grapple Buckets that suit different industries and applications. Their products are known for their reliability, durability, and customized designs that meet the specific needs of their clients.In conclusion, the Excavator Grapple Bucket is a versatile and efficient solution for handling large and heavy materials in industrial settings. Various industrial sectors such as construction, mining, forestry, and waste management have benefitted from the adoption of this bucket, resulting in increased productivity, reduced manual labor, and efficient workflow management. With further advancements in technology, Excavator Grapple Buckets are set to become more sophisticated, making them an indispensable tool for industries across the globe.