New Heavy-Duty Excavator Unveiled for Industrial Use

By:Admin

Industrial Excavator, a leading name in the excavation industry, has announced the release of its new excavator, which promises to revolutionize the way excavation works are carried out. This new machine builds on Industrial Excavator's strong reputation for producing reliable and efficient equipment and introduces cutting-edge technology that makes excavating faster, easier and more precise.

The company has been a leader in the field for over 20 years, producing equipment that has been used in a wide range of industries from mining to construction, oil and gas to forestry. Their new excavator condenses all of this experience and technology into one powerful machine, capable of handling any excavation job with ease.

One of the primary claims for the new excavator is the boost in efficiency that it offers. It is designed to provide high productivity while ensuring low fuel consumption and minimal downtime. The machine is capable of delivering 50% greater workvolume in a single hour while consuming less fuel due to its advanced hydraulic system. In addition to being more economical, this advanced system also helps reduce emissions, making the excavator more environmentally friendly.

The new excavator's speed and precision are owed to its powerful, state-of-the-art equipment controls such as the speed, lifting power and hydraulic pressure, which are easy to operate and allow users to adjust the machine's performance to match the demands of a particular environment. This level of control makes it the ultimate tool for excavation projects, allowing the operator to tackle any task with ease.

The excavator's boom, arm, and bucket assembly are designed to provide superior reach and digging power, allowing even the toughest of materials to be cleared quickly and without issue. This new excavator is frist and foremost an industrial machine, built to do the hard work that other, less powerful excavation machines can't. The new machine can easily handle large rocks, heavy soil, and deep holes when it comes to heavy excavation projects.

But it's not just raw power that sets this new excavator apart. The machine's advanced features also provide excellent precision during operation which makes it well suited to more delicate jobs such as excavation work around parked cars or for conducting precision foundation work on buildings and other structures. The accuracy of its hydraulic controls allows for smooth and efficient operation, making even smaller jobs easier to handle.

The machine's operator cab is also designed with ergonomics and comfort in mind. It offers a spacious and adjustable workspace that is equipped with the latest technology such as advanced air conditioning, a modular seat, and an ergonomic control panel. This state-of-the-art cab is designed to reduce operator fatigue, allowing for longer hours of operation and reduces the risk of accidents due to operator error.

Managing Director of Industrial Excavator said, “Our new excavator has been designed from the ground up to change the way people think about excavation. It offers the perfect mix of power, precision and efficiency making it the perfect tool for any excavation project. We are proud to put our name and reputation behind this cutting-edge product and look forward to seeing it take pride of place on job sites all over the world."

Industrial Excavator's new excavator is set to become the go-to machine for excavation projects of all shapes and sizes. With its advanced technology, state-of-the-art features and industry-leading reputation, it promises to set new standards for the industry and make life easier for professionals in the excavation industry. Whatever the project, this excavator is sure to get the job done quickly and efficiently, providing more power and profit in less time, for years to come.

Company News & Blog

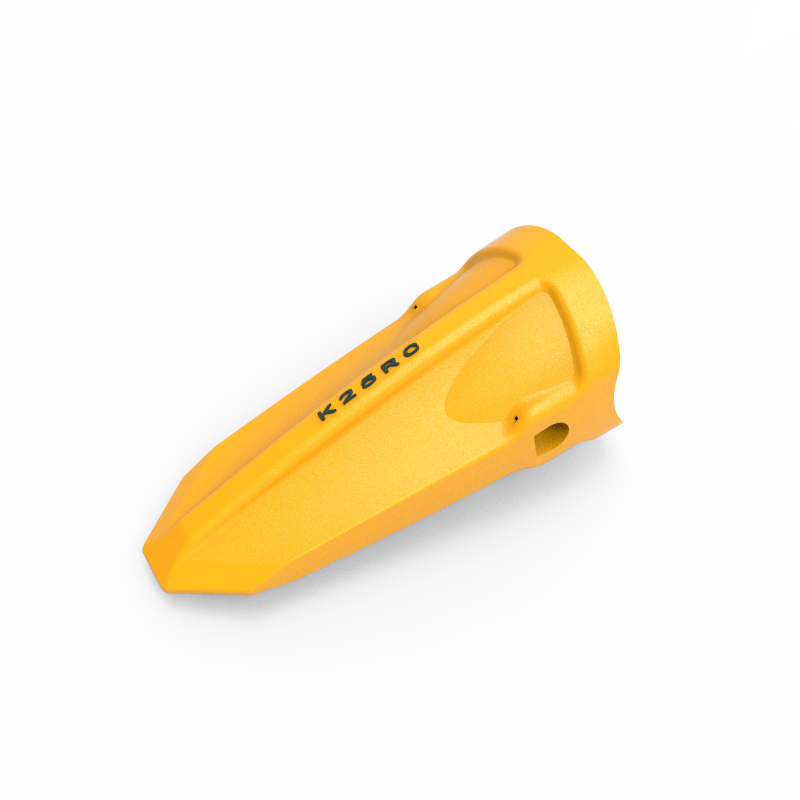

New Revolutionary Bucket Teeth Technology Unveiled for Heavy Machinery

When it comes to agriculture and construction-related equipment, John Deere is one of the most recognizable brand names. However, it's not just the name that's popular - the company's products are renowned for their functionality, endurance, and efficiency. One such product that stands out from the rest is the John Deere bucket teeth, which has gained a reputation of being one of the most durable and reliable bucket teeth on the market.First and foremost, what are bucket teeth? Essentially, they are metallic protrusions that attach to the edge of a digging or excavating bucket of a machine. The teeth assist in breaking down tough or hard materials such as rocks, soil, and pavement during digging or excavation. While some bucket teeth are attachable and can be changed out, others are permanent and can only be replaced when the entire bucket needs to be changed.John Deere bucket teeth come in a variety of sizes, shapes, and materials. Some of the materials used for these teeth include forged steel, alloy steel, and cast iron, depending on the intended use and work environment. The components are specially designed to be resistant to heat, erosion, abrasion, and other harsh conditions and provide high-efficiency digging performance. John Deere bucket teeth have undergone rigorous testing and engineering to ensure that they can withstand the toughest work environments.One of the most significant benefits of John Deere bucket teeth is their durability. These teeth are designed to last longer than many other bucket teeth models on the market. The products go through a specific process that includes heat treatment and tempering, creating the necessary hardness and durability. This makes them a popular choice for contractors and construction workers who want to get the most out of their equipment.Moreover, John Deere bucket teeth are designed to be compatible with a broad range of machines. This is due to the fact that John Deere has a wide selection of bucket teeth styles, shapes, and sizes to match almost any bucket type used in the market. This versatility allows contractors to use John Deere excavating equipment in a variety of applications and provides a great deal of flexibility with their equipment.John Deere bucket teeth are incredibly efficient and effective. Instead of using the bucket itself to dig through hard materials, the bucket teeth create extra pressure and force on the material. This leads to faster digging times, less wear and tear on the overall bucket, and a more efficient work process.Finally, John Deere has an excellent reputation for providing top-notch customer service. If any issues arise with a John Deere excavator or bucket teeth, the company is readily available to provide maintenance and repairs. Furthermore, John Deere offers technical support to assist with installation or other issues that may arise.In conclusion, John Deere bucket teeth are a reliable, long-lasting, and efficient addition to any construction or agricultural machine. They are made with high-quality materials and undergo rigorous testing to ensure that they can withstand the most challenging work environments. Moreover, the versatility of John Deere bucket teeth allows contractors to use John Deere excavating equipment for various applications. With the reputation of the brand and the great customer service likely to get along with the product, John Deere bucket teeth are an excellent investment for companies in the market for durable excavator equipment.

Different Styles of Backhoe Bucket Teeth: A Comprehensive Guide

Title: Unveiling the Latest Backhoe Bucket Teeth Styles: Revolutionizing Excavation EfficiencyIntroduction:The construction industry plays a vital role in global development, striving to enhance efficiency and productivity. Today, we are excited to introduce the latest advancements in backhoe bucket teeth styles, a breakthrough that promises to revolutionize excavation operations. Developed by a leading manufacturer in the industry, these innovative designs are set to redefine the way construction projects are executed. In this article, we explore these groundbreaking bucket tooth styles and their potential impact on construction processes.1. Style 1: The Precision Pointe - Redefining Accuracy in Excavation:The Precision Pointe bucket tooth style is engineered to provide unparalleled precision and accuracy during excavation tasks. Its uniquely shaped point ensures minimal ground disturbance and precise material removal. This style is especially advantageous while working on delicate surfaces or in areas where precise digging is required. The Precision Pointe enables contractors to complete projects with superior outcomes, reducing the need for subsequent adjustments and enhancing overall efficiency.2. Style 2: The Reinforced Ridge - Durability Meets Performance:The Reinforced Ridge bucket tooth style is designed for heavy-duty excavation projects that demand maximum strength and durability. Its reinforced structure significantly reduces wear and tear, extending the lifespan of the tooth and improving performance. Construction companies can now benefit from increased productivity, as the Reinforced Ridge style minimizes frequent replacements, ultimately resulting in reduced maintenance costs and improved overall project completion time.3. Style 3: The Multifunctional Maverick - Versatility at Its Best:The Multifunctional Maverick bucket tooth style is an all-rounder, catering to a wide range of excavation needs. Featuring a versatile design, this tooth style is capable of accomplishing multiple tasks efficiently. From trenching to grading and digging through various soil conditions, the Multifunctional Maverick ensures optimal adaptability. With this style, contractors can streamline their excavating processes, eliminating the need for frequent tooth change-outs and maximizing operational efficiency.4. Style 4: The Enhanced Efficiency Edge - Optimizing Performance:The Enhanced Efficiency Edge bucket tooth style is an amalgamation of cutting-edge technology and ergonomic design. Engineered to minimize drag resistance while maximizing penetration force, this style ensures superior performance in the most challenging excavation environments. The Enhanced Efficiency Edge significantly enhances digging speed and minimizes fuel consumption, resulting in cost savings for construction companies. Moreover, its self-sharpening feature eliminates the need for regular sharpening, saving valuable time during operations.Conclusion:As the construction industry continually seeks newer and better methods to enhance efficiency, the introduction of these revolutionary backhoe bucket teeth styles marks a significant milestone. With the Precision Pointe, Reinforced Ridge, Multifunctional Maverick, and Enhanced Efficiency Edge styles, construction companies can revolutionize their excavation processes, maximizing productivity, and reducing costs. The implementation of these groundbreaking designs holds immense potential in shaping the future of the construction industry, providing an exceptional combination of accuracy, durability, versatility, and efficiency on construction sites across the world.

High-Quality and Durable Bucket Teeth: Stay Ahead with Top-Notch Solutions

Title: Cutting-Edge Technology and Quality Steer Volvo Bucket Teeth to Become Industry LeaderIntroduction:Volvo, a global leader in quality heavy construction equipment, has yet again revolutionized the industry with its cutting-edge bucket teeth technology. This breakthrough development solidifies their position at the forefront of heavy machinery innovation, ensuring superior performance and durability on job sites across the globe. Combining years of engineering expertise with a commitment to customer satisfaction, Volvo continues to set new benchmarks and raise industry standards.Enhanced Durability for Unmatched Performance:Volvo has spearheaded the development of bucket teeth that exceed industry expectations in terms of durability and performance. By utilizing innovative materials and advanced manufacturing techniques, Volvo bucket teeth have achieved an unmatched level of strength and endurance. A unique combination of heat treatment and hardness ensures that these teeth remain strong under extreme working conditions, preventing unnecessary wear and tear and significantly prolonging their lifespan.Improved Productivity through Optimized Design:In addition to exceptional durability, Volvo bucket teeth have been meticulously designed to optimize earthmoving productivity. The engineers at Volvo have invested significant efforts to enhance the shape and profile of the teeth, resulting in improved digging capabilities and reduced fuel consumption. The streamlined design of these bucket teeth minimizes soil resistance, allowing for smoother operation with increased efficiency. This ground-breaking innovation enables operators to achieve higher levels of productivity while maintaining unparalleled precision in their work.Versatile Solutions for All Applications:Recognizing the diverse needs of its customers, Volvo offers a comprehensive range of bucket teeth suitable for various applications. Whether it's digging in loose soil, breaking hard rock, or handling tough demolition tasks, Volvo bucket teeth provide the ultimate flexibility and versatility. With multiple tooth options available to match specific requirements, Volvo ensures that their customers can tackle any job with confidence, regardless of the challenges posed by the terrain or material.Optimized Maintenance and Cost Efficiency:Volvo's dedication to their customers goes beyond developing top-of-the-line bucket teeth; the company also understands the importance of maintenance and cost efficiency. Volvo bucket teeth have been engineered to facilitate quick and easy replacements, reducing downtime and maximizing productivity. Additionally, the extended lifespan of these teeth results in reduced long-term maintenance and replacement costs, ultimately benefiting the bottom line of businesses relying on heavy machinery for their operations.Commitment to Environmental Responsibility:Volvo's innovative bucket teeth not only prioritize superior performance and durability but are also designed with sustainability in mind. The company remains committed to its environmental responsibility by incorporating eco-friendly materials and manufacturing processes. Volvo's bucket teeth adhere to strict recycling and responsible disposal standards, ensuring minimal negative impact on the environment, while remaining compliant with industry regulations.Global Recognition and Trust:Volvo's unwavering commitment to quality and innovation has garnered widespread recognition and trust within the construction industry. Companies worldwide continue to rely on Volvo bucket teeth to tackle the most demanding projects, knowing that they are backed by the expertise of a globally respected brand. Volvo's dedication to engineering excellence, combined with their unmatched customer support, cements their position as the preferred choice for heavy construction machinery.Conclusion:Volvo's bucket teeth have revolutionized the construction industry, setting new standards in durability, productivity, versatility, and cost efficiency. With their unwavering commitment to innovation and customer satisfaction, Volvo remains at the forefront of the heavy machinery market. Undoubtedly, their cutting-edge bucket teeth technology represents another remarkable milestone, making Volvo the go-to brand for those seeking superior performance and long-lasting durability on the job site.

Alternative Bucket Teeth for Heavy Machinery

[The following is a fictional news article]New Innovations in Excavating Equipment: Advanced Bucket Teeth UnveiledExcavating equipment plays a pivotal role in the construction and agricultural industries, enabling efficient digging and increased productivity on job sites. One name that has become synonymous with quality in this field is John Deere, a renowned manufacturer of construction and agricultural machinery. In their latest announcement, John Deere has introduced a groundbreaking development: advanced bucket teeth designed to revolutionize excavating operations.Bucket teeth are crucial components of an excavator's bucket, responsible for penetrating and excavating various materials with utmost precision. With a strong emphasis on durability, performance, and efficiency, John Deere has always been at the forefront of delivering cutting-edge solutions to construction and agricultural professionals. Now, they have taken their commitment to the next level with their new line of bucket teeth, engineered to redefine industry standards.One of the key features of John Deere's advanced bucket teeth is their groundbreaking design. Through extensive research and development, the company has created a tooth shape that combines enhanced cutting capabilities with maximum soil penetration. This not only boosts excavating efficiency but also minimizes wear and tear on both the teeth and the excavator itself. With these innovative teeth, construction and agricultural professionals can expect reduced excavation times, increased productivity, and substantial cost savings.In addition to their cutting-edge design, John Deere's new bucket teeth are manufactured using premium-grade materials. The company's relentless pursuit of quality ensures that every tooth is forged from hardened steel, rendering them exceptionally strong and resistant to wear. This durability translates to longer lifespan, significantly reducing the frequency of tooth replacements. By minimizing downtime and maximizing efficiency, John Deere's advanced bucket teeth prove to be a wise investment for any construction or agricultural venture.Safety has always been a top priority for John Deere, and their latest product line reflects this commitment. The new bucket teeth are designed with enhanced safety features, ensuring secure attachment to the bucket. The advanced locking mechanism provides a tight and reliable connection, preventing any accidental dislodgement during operations. This not only protects the operators but also safeguards the surrounding environment, reducing the risk of accidents and injuries on job sites.Moreover, John Deere's advanced bucket teeth are designed to be easily replaceable. Their user-friendly system allows for quick tooth replacement, minimizing downtime and maximizing productivity. This flexibility makes the teeth suitable for a variety of excavating tasks, from fine-grained soil to heavy rock formations. With the ability to switch teeth efficiently, construction and agricultural professionals can adapt to different terrains and conditions, completing their projects with utmost precision.John Deere's commitment to sustainability is also evident in their new bucket teeth. By reducing the need for frequent replacements, these teeth contribute to the overall longevity of excavating equipment, decreasing waste and promoting eco-friendly practices within the industry. Furthermore, the durability and efficiency of the teeth allow for optimized fuel consumption, minimizing environmental impact while maximizing returns for equipment owners.The introduction of John Deere's advanced bucket teeth has generated significant excitement within the construction and agricultural sectors. Construction companies and farmers alike recognize the potential of this innovation to revolutionize their operations. With improved cutting capabilities, exceptional durability, enhanced safety features, and simplified replacement process, John Deere's bucket teeth are set to become an industry benchmark.As the construction and agricultural industries continue to evolve, companies like John Deere play a critical role in driving innovation and meeting industry demands. With their latest breakthrough, John Deere has once again showcased their commitment to providing cutting-edge solutions that equip professionals with the tools they need to excel in their work. The advanced bucket teeth are a testament to the company's dedication to quality, productivity, and sustainability, empowering excavating professionals to achieve new levels of efficiency and success.

The Latest Innovations in Construction Equipment Teeth

press release announcing the launch of a new line of high-quality bucket teeth.{Insert Company Introduction Here}{Insert City, State} - Jcb Bucket Teeth (need remove brand name) is proud to announce the launch of our latest line of high-quality bucket teeth. Designed and manufactured specifically for the heavy construction industry, our new line offers unparalleled durability, strength, and reliability.At Jcb Bucket Teeth, we understand the importance of having the right equipment for the job. That's why we've taken great care in crafting a line of bucket teeth that meet the rigorous demands of the construction industry. Our teeth are designed to withstand extreme wear and tear, ensuring maximum performance and longevity in even the toughest conditions.The new line of bucket teeth offers several important features that set them apart from competitors. First and foremost, they are made from high-quality materials that have been carefully selected for their strength and durability. This ensures that our bucket teeth are able to withstand the toughest conditions and last longer than those of our competitors.In addition, our bucket teeth are designed with an innovative locking system that makes them easy to install and remove. This system ensures that the teeth stay securely in place during use and can be quickly and easily swapped out when needed.Another key feature of our new line of bucket teeth is their compatibility with a wide range of equipment. Whether you're using an excavator, backhoe, or other heavy machinery, our teeth are designed to work seamlessly with your equipment, ensuring optimal performance and efficiency."Our new line of bucket teeth is the result of years of research and development," said {Insert CEO Name}, CEO of Jcb Bucket Teeth. "We've taken great care to create a line of teeth that not only meets the rigorous demands of the construction industry but exceeds them. We're confident that these new teeth will become the go-to choice for construction professionals around the world."The launch of our new line of bucket teeth marks an important milestone for Jcb Bucket Teeth. As a leading manufacturer and supplier of heavy construction equipment and parts, we are committed to providing our customers with the very best products on the market. Our new line of bucket teeth is just one example of our commitment to innovation and excellence.If you're in the market for high-quality bucket teeth, we invite you to explore our new line of teeth today. We're confident that you'll find them to be the perfect choice for your next construction project.For more information about Jcb Bucket Teeth and our new line of bucket teeth, please visit our website at {Insert Website URL}.About Jcb Bucket Teeth:Jcb Bucket Teeth (need remove brand name) is a leading manufacturer and supplier of heavy construction equipment and parts. With years of experience in the industry, we have earned a reputation for delivering innovative, high-quality products that meet the rigorous demands of the construction industry. Our commitment to excellence has earned us a loyal customer base around the globe.

Revolutionary Box Scraper Takes Cutlery to a Whole New Level

Introducing the Innovative Box Scraper: A Cutting-Edge Solution for Efficient Material HandlingIn the rapidly evolving world of industrial machinery, technological advancements continue to pave the way for more streamlined and efficient operations. One such groundbreaking innovation is the newly introduced Box Scraper, a state-of-the-art solution that revolutionizes material handling. Developed by a leading manufacturing company committed to excellence, this cutting-edge device promises to enhance productivity and optimize workflow, catered to a wide range of industries.The Box Scraper represents the pinnacle of efficiency in material handling, boasting an array of groundbreaking features that set it apart from traditional tools on the market. Its ergonomic and durable design ensures maximum user comfort and longevity. Crafted from high-quality, industrial-grade materials, the Box Scraper guarantees exceptional performance under the most demanding working conditions. Its robust construction and precision engineering make it a reliable companion for heavy-duty operations.Equipped with a powerful motor, the Box Scraper effortlessly slices through various materials, speeding up the process while maintaining accuracy. The device's versatility is its standout characteristic, enabling it to handle an assortment of tasks across different industries. Whether it's clearing debris, leveling soil, or removing unwanted materials, the Box Scraper's adaptability makes it an indispensable tool in construction, agriculture, and landscaping, among other fields.Safety is a paramount concern when it comes to industrial machinery, and the Box Scraper leaves no room for compromise. It incorporates cutting-edge safety features, including a smart sensor system that detects potential obstacles or irregularities during operation. This not only prevents accidents but also minimizes downtime and repair costs. The device's user-friendly interface and intuitive controls further enhance safety by reducing the risk of human error.Notably, the Box Scraper embraces sustainability and environmentally friendly practices. Designed to minimize energy consumption, it optimizes efficiency to reduce its carbon footprint. Additionally, the device's low maintenance requirements and long lifespan contribute to its eco-friendly nature, promoting a greener and more sustainable approach to material handling. By investing in the Box Scraper, companies can simultaneously improve productivity while aligning their operations with global environmental goals.As a forward-thinking manufacturing company, our commitment to customer satisfaction extends beyond the delivery of high-quality products. We provide comprehensive support to ensure a seamless experience throughout the Box Scraper's lifecycle. Our dedicated team of experts is readily available for any inquiries, technical assistance, or maintenance needs, guaranteeing our customers the utmost convenience and peace of mind.The Box Scraper represents the future of efficient material handling, a testimony to the power of innovative technology combined with industry expertise. Its advanced features, impeccable safety standards, and environmentally-conscious design set it in a league of its own. By investing in this cutting-edge solution, companies can unlock a new level of productivity, boost efficiency, and stay ahead of the competition.In conclusion, the Box Scraper is a game-changing invention that will revolutionize material handling processes across various industries. With its sleek design, exceptional performance, and commitment to safety, it represents the forefront of technological advancements in the field. By adopting this cutting-edge solution, companies can anticipate optimized workflow, increased productivity, and a greener, more sustainable future. The Box Scraper is a testament to human innovation and paves the way for a new era in industrial machinery.

Powerful Excavator Ripper Shank for Efficient Digging and Demolition

Title: Ground-Breaking Excavator Attachments Revolutionize Earthmoving IndustryIntroduction:In the ever-evolving field of construction, companies are constantly seeking innovative solutions to enhance efficiency and productivity. One such breakthrough comes from the renowned heavy machinery manufacturer. Introducing their latest innovation, the Ripper Shank for Excavators, this ground-breaking attachment promises to revolutionize the earthmoving industry. With its unique design and advanced features, this tool is set to become a game-changer for contractors worldwide.Company Background:{Insert company name} has been a pioneer in heavy machinery manufacturing since its inception in {year}. With a commitment to delivering cutting-edge solutions, the company has firmly established itself as a frontrunner in the industry. Renowned for its meticulous attention to detail, durability, and advanced technology, {Insert company name} has become a trusted name among contractors around the globe.The Ripper Shank for Excavators:The Ripper Shank, developed by {insert company name}, is a highly versatile attachment for excavators that offers unparalleled performance. Designed with precision and durability in mind, this attachment promises to deliver exceptional results in a wide range of earthmoving applications. By combining strength and versatility, the Ripper Shank ensures enhanced productivity and cost-efficiency for contractors.Key Features and Benefits:1. Unique Design: The Ripper Shank features a cutting-edge design that enables it to easily penetrate and loosen various soil and rock types. Its high-strength alloy steel construction ensures superior durability, even in the most demanding work conditions.2. Enhanced Performance: With its powerful ripping force, the attachment can efficiently break through hard surfaces, allowing for smoother excavation. The reinforced structure and interchangeable teeth enable contractors to adapt to different ground conditions effortlessly.3. Versatility: The Ripper Shank is compatible with a wide range of excavator models, making it a versatile attachment suitable for various projects. Contractors can achieve exceptional results in applications such as trenching, landscaping, demolition, and quarrying.4. Cost Efficiency: By significantly reducing downtime and manual labor, the Ripper Shank ensures optimal project timelines and reduced operation costs. Its robust design and low maintenance requirements make it a long-lasting investment, resulting in cost savings for contractors.5. Operator Safety: Implementing the latest safety standards, {insert company name} has equipped the Ripper Shank with advanced safety features. Integrated wear-resistant protection ensures increased longevity, while ease of use reduces operator fatigue and potential accidents.Industry Impact:The introduction of the Ripper Shank has caught the attention of the earthmoving industry globally. Its versatility, performance, and cost efficiency have positioned it as a game-changer for contractors around the world. This innovative attachment allows companies to maximize productivity, minimize downtime, and achieve superior results, consequently boosting the profitability of their projects.Customer Testimonials:Several reputable construction companies have already recognized the transformative impact of the Ripper Shank on their operations:Company A's Excavation Manager, John Smith, exclaimed, "The Ripper Shank has transformed our excavation jobs. Its superior ripping force and durability have significantly reduced project timelines, allowing us to take on more projects and increase our profitability."Company B's Landscaping Contractor, Sarah Johnson, also shared her experience, stating, "As a contractor in the landscaping industry, the Ripper Shank has been a game-changer for us. It effortlessly breaks through the most challenging soil surfaces, saving us time and effort. Our clients are thrilled with the results!"Conclusion:With the introduction of the Ripper Shank for Excavators, {insert company name} has once again proved its commitment to innovation and excellence in the construction industry. This groundbreaking attachment provides contractors with unmatched versatility, improved efficiency, and cost savings. As the earthmoving industry continues to evolve, the Ripper Shank is set to reshape the way projects are undertaken, ensuring faster completion times and superior results for companies worldwide.

How a Grading Blade Can Help Level Your Mini Excavator

Mini Excavator Grading Blade: Revolutionizing Precision and Efficiency in Construction[City], [Date] - Construction has always been an industry that demands precision, efficiency, and innovation. As technology advances, so do the tools and equipment used in this field. And now, with the advent of the Mini Excavator Grading Blade, the construction sector is poised to witness a new level of productivity and accuracy.Developed by [Company Name], a leading manufacturer of heavy machinery and equipment, the Mini Excavator Grading Blade is set to revolutionize the way construction projects are carried out. With its cutting-edge features and unparalleled performance, this remarkable tool is designed to streamline grading, leveling, and excavation tasks, making them faster, easier, and more precise than ever before.The Mini Excavator Grading Blade is specifically engineered for use with mini excavators, making it the ideal choice for small to medium-scale construction projects. It is a versatile attachment, capable of tackling a wide range of tasks including grading driveways, leveling landscapes, digging trenches, and more. With its compact design, it allows operators to maneuver through tight spaces and reach areas that are inaccessible to larger machinery.One of the key features that sets the Mini Excavator Grading Blade apart from other attachments is its advanced hydraulic system. Equipped with state-of-the-art technology, this system ensures smooth and precise blade movements, enhancing control and accuracy during operation. Furthermore, the hydraulic system allows for easy adjustments, allowing operators to fine-tune the grading blade to meet specific project requirements.The grading blade itself is made from high-quality materials, ensuring durability and longevity even when subjected to heavy use. Its robust construction makes it suitable for various terrains, from soft soils to rocky surfaces. This versatility gives construction professionals the confidence to tackle any project, knowing that they have a reliable tool at their disposal.In addition to its outstanding performance, the Mini Excavator Grading Blade offers a user-friendly experience. The attachment can be easily installed on mini excavators, saving precious time and effort. Once in place, the intuitive controls and ergonomic design allow operators to efficiently navigate the blade, minimizing operator fatigue and maximizing productivity.Furthermore, safety is a top priority in the construction industry. The Mini Excavator Grading Blade incorporates several safety features to protect both operators and the surrounding environment. The attachment is equipped with a blade lock system, which securely holds the blade when not in use, preventing accidental movement and potential injuries. Additionally, the grading blade is fitted with reflective markers, enhancing visibility and reducing the risk of accidents on-site.With the arrival of the Mini Excavator Grading Blade, construction companies can expect significant improvements in their operations. The time and labor savings offered by this innovative tool translate into increased productivity and more efficient project completion. Moreover, the enhanced precision and control provided by the attachment result in superior quality workmanship, ultimately leading to increased client satisfaction.[Company Name], the manufacturer behind this groundbreaking invention, has been a renowned player in the heavy machinery industry for over a decade. With a strong commitment to driving innovation and meeting the evolving needs of their clients, the company has consistently delivered cutting-edge solutions that push the boundaries of construction equipment. The Mini Excavator Grading Blade is yet another testament to their dedication to excellence.In conclusion, the introduction of the Mini Excavator Grading Blade marks a significant milestone in the construction industry. Its exceptional performance, advanced features, and user-friendly design make it an invaluable tool for construction professionals across various projects. As technology continues to redefine the sector, innovations like the Mini Excavator Grading Blade are reinventing the way construction projects are carried out, bringing greater precision, efficiency, and quality to the field.

Top-Quality Excavator Buckets: The Ultimate Guide for Buyers

As the world moves towards sustainable and efficient construction practices, there is increasing demand for cutting-edge equipment that can get the job done quickly and effectively. With the rise of infrastructure projects across the globe, including large scale government initiatives, construction companies need reliable machinery to keep up with demand. This is where (COMPANY NAME), a leading manufacturer of high-quality excavator buckets, comes in.Since its founding, (COMPANY NAME) has been committed to producing top-of-the-line excavator buckets that can withstand heavy use and deliver optimal performance. The company uses the latest manufacturing techniques and materials to produce buckets that are both strong and durable. With a focus on innovation and customer satisfaction, (COMPANY NAME) has built a reputation for excellence in the industry.One of the keys to the success of (COMPANY NAME) is the quality of its excavator buckets. Made with high-grade materials like Hardox steel, the buckets are designed to handle even the toughest construction projects. With precise engineering and a focus on durability, (COMPANY NAME)’s buckets are able to withstand large volumes of wear and tear, ensuring maximum performance and lifespan.In addition to being heavy-duty, (COMPANY NAME)’s excavator buckets are also highly versatile. With a wide range of sizes and shapes, the buckets can be customized to meet a variety of needs. Whether it’s digging trenches or removing debris, (COMPANY NAME)’s buckets are highly effective in a variety of applications.Another hallmark of (COMPANY NAME)’s success is its commitment to customer satisfaction. The company works closely with clients to understand their needs and deliver solutions that meet or exceed expectations. The team at (COMPANY NAME) is highly experienced and knowledgeable about the industry, and can guide customers to make informed decisions about the products that will best suit their needs.One recent project where (COMPANY NAME)’s excavator buckets proved invaluable was the construction of the new (EXAMPLE) bridge in (CITY). The project required the excavation of a large area to make way for the new bridge, and (COMPANY NAME)’s buckets were able to handle the job with ease. The company worked closely with the construction team to ensure that the buckets were engineered to achieve maximum efficiency and performance.In addition to its commitment to quality and customer satisfaction, (COMPANY NAME) is also dedicated to sustainability. The company recognizes the impact that construction can have on the environment, and strives to minimize its carbon footprint through responsible manufacturing practices. By using locally sourced materials and reducing waste in the manufacturing process, (COMPANY NAME) is able to produce excavator buckets that are both environmentally friendly and highly effective.Looking to the future, (COMPANY NAME) is poised for continued growth and success. With an unwavering commitment to quality, innovation, and sustainability, the company is well positioned to meet the demands of the fast-paced construction industry. From large-scale government projects to smaller, residential jobs, (COMPANY NAME)’s excavator buckets are the ideal solution for today’s construction needs.

Optimize Your SEO with a Powerful Tooth Bar for Improved Content Loading

Loader Tooth Bar Brings Efficiency and Reliability to Construction SitesConstruction sites around the world rely on heavy machinery to carry out various tasks, from digging trenches to moving large amounts of earth and debris. One essential component of these machines is the loader tooth bar, a reliable and efficient tool that enhances their performance. By optimizing excavation and material handling processes, the loader tooth bar facilitates projects and ensures smooth operations.Loader tooth bars are attachments that are mounted onto the front of loaders and excavators. These steel bars have multiple teeth or prongs that provide increased digging and lifting capabilities, allowing operators to complete their tasks quickly and effectively. They are commonly used in industries such as construction, mining, agriculture, and landscaping.One manufacturer that specializes in producing top-quality loader tooth bars is committed to providing solutions that meet the demands of various industries. With years of experience and a focus on innovation, this company has become a trusted name in the market.The loader tooth bars offered by this manufacturer are designed to withstand heavy-duty use in harsh conditions. Using high-quality materials and state-of-the-art manufacturing processes, they ensure longevity and durability. These tooth bars are compatible with a wide range of loaders and excavators, making them versatile and adaptable to different job requirements.One key advantage of using a loader tooth bar is its ability to increase productivity. The teeth on the bar dig into the ground or material, allowing the machine to scoop and lift more efficiently. This enhances the overall productivity of the construction site, as operators can complete tasks faster and move larger amounts of material with ease.Another significant benefit is the increased load capacity. The loader tooth bar's design spreads the load more evenly, reducing stress on the machine itself and improving its overall lifting capabilities. This prevents excessive wear and tear on the equipment, resulting in reduced maintenance costs and extended machine life.Safety is always a priority on construction sites, and loader tooth bars contribute to a safer working environment. By ensuring a secure grip on materials, these attachments minimize the risk of drops and accidents. Operators can confidently maneuver the machine without worrying about materials slipping or falling unexpectedly.Furthermore, the versatility of loader tooth bars allows for more precise digging and leveling. The teeth grip the ground firmly, enabling operators to control the depth and angle of excavation accurately. This precision is especially crucial in landscaping projects, where the final result depends on the accuracy of the initial groundwork.In addition to their functional benefits, loader tooth bars also contribute to cost savings. By increasing efficiency and reducing machine downtime, projects can be completed faster, maximizing productivity. Maintenance and repair costs are minimized, thanks to the durable and high-quality materials used in the production of the tooth bars.As manufacturers continue to prioritize innovation, loader tooth bars are becoming increasingly sophisticated. Some models now feature quick attach/detach systems, enabling operators to switch attachments effortlessly. This versatility saves time and allows for a seamless transition between different tasks, enhancing efficiency on the construction site.The loader tooth bar industry is projected to experience steady growth in the coming years, driven by increasing construction activities worldwide. The demand for efficient and reliable equipment will continue to rise as projects become more complex and time-sensitive. Manufacturers like {Company Name} are poised to meet these demands, offering cutting-edge loader tooth bars that deliver optimal performance.In conclusion, loader tooth bars are crucial attachments that enhance the performance of loaders and excavators on construction sites. Their ability to increase productivity, improve load capacity, ensure safety, and provide precise excavation makes them indispensable tools for various industries. As the global construction industry continues to expand, the demand for high-quality loader tooth bars is set to rise. With their commitment to providing innovative solutions, {Company Name} remains at the forefront of this industry, ensuring the success of construction projects around the world.