Key Components of a Backhoe Excavator Explained

By:Admin

The new backhoe excavator boasts several key features that set it apart from its predecessors. The powerful engine, combined with advanced hydraulic systems, allows for greater digging force and improved lifting capabilities. The machine's rugged construction and durable components ensure long-lasting performance, even in the most challenging work environments.

One of the most notable features of the new backhoe excavator is its enhanced operator comfort. The spacious cab is ergonomically designed for maximum visibility and ease of operation, reducing operator fatigue during long hours on the job. The intuitive control system and adjustable seat further contribute to a comfortable and efficient work environment.

In addition to its superior performance and operator comfort, the backhoe excavator also prioritizes safety. The machine is equipped with advanced safety features, including a ROPS/FOPS certified cab, rear-view camera, and anti-slip steps and handrails. These features are designed to ensure the well-being of the operator and those working in the vicinity of the machine.

One of the highlights of the new backhoe excavator is its versatility. Equipped with a range of attachments, including buckets, hammers, and augers, the machine is capable of tackling a variety of tasks with ease. Whether it's digging trenches, breaking up concrete, or lifting heavy materials, the backhoe excavator is up to the challenge.

ABC Manufacturing Company has a long-standing reputation for producing high-quality heavy equipment that meets the demands of the modern construction industry. With a focus on innovation and continuous improvement, the company has established itself as a leader in the field.

"Our new backhoe excavator is the result of extensive research and development, aimed at meeting the evolving needs of our customers," said John Smith, CEO of ABC Manufacturing Company. "We are proud to introduce a machine that not only delivers exceptional performance but also prioritizes operator comfort and safety."

The launch of the new backhoe excavator is set to have a significant impact on the construction industry. Its advanced features and unparalleled performance are expected to streamline construction projects and improve overall efficiency.

"We believe that our new backhoe excavator will set a new standard for the industry," added Smith. "We are confident that it will be well-received by construction professionals who are looking for a reliable and versatile machine that can handle a wide range of tasks."

In conclusion, the new backhoe excavator from ABC Manufacturing Company is a testament to the company's commitment to innovation and excellence. With its advanced features, superior performance, and focus on operator comfort and safety, the machine is poised to make a significant impact in the construction industry. As the demand for efficient and reliable heavy equipment continues to grow, the new backhoe excavator is set to meet and exceed the expectations of construction professionals around the world.

Company News & Blog

How Cutting Teeth for Excavators Work: A Complete Guide

[Title: Innovative Cutter Teeth Revolutionize Industrial Machining]In the ever-evolving world of industrial machining, one company is making waves with its revolutionary cutter teeth technology. Known for their commitment to innovation and efficiency, this cutting-edge company has introduced a game-changing solution that promises to enhance productivity and reduce costs in the manufacturing industry. With a strong focus on research and development, they have successfully developed cutter teeth that outperform their competitors in terms of durability, precision, and overall performance.Cutter teeth play a crucial role in various machining processes, including milling, turning, and drilling. Traditionally, these teeth are known to wear out quickly, resulting in frequent replacements and expensive downtime. However, with the introduction of this new brand's cutter teeth, these issues are becoming problems of the past.The secret behind the success of this brand's cutter teeth lies in their innovative design and superior materials. Through extensive research and collaboration with industry experts, the company has developed a unique tooth geometry that ensures optimal performance and longevity. Additionally, they have carefully selected high-grade materials that are highly resistant to wear and tear, guaranteeing a longer lifespan for their cutter teeth.One of the key advantages of this brand's cutter teeth is their exceptional performance in demanding machining applications. Whether it's cutting through tough materials or performing intricate precision work, these teeth deliver remarkable results. This enhanced performance translates to improved productivity for manufacturers, as they can now complete jobs faster and with greater accuracy.Furthermore, the extended lifespan of these cutter teeth significantly reduces maintenance costs. Manufacturers no longer need to frequently replace worn-out teeth, resulting in substantial savings in terms of both time and money. This cost-effectiveness is especially beneficial for small and medium-sized enterprises that rely heavily on their machining equipment but often face budget constraints.The company's commitment to excellence does not stop at product development. They have also established a robust customer support system to ensure that their clients receive the best experience possible. This includes dedicated technical assistance and prompt response to any queries or concerns. By fostering strong relationships with their customers, the company aims to provide unmatched service and build trust within the industry.Moreover, the brand's cutter teeth are not limited to specific industries or applications. They have successfully catered to a wide range of sectors, including aerospace, automotive, energy, and more. This versatility is a testament to their dedication to serving various industries and fulfilling diverse machining needs.As the manufacturing industry continues to evolve, it is crucial for businesses to adapt and embrace innovative solutions. This new brand's cutter teeth offer a unique opportunity for manufacturers to stay ahead of the competition while optimizing their operations. With their unmatched performance, superior durability, and exceptional customer support, it is evident why this company has garnered significant attention within the industry.In conclusion, the introduction of this brand's cutter teeth marks a milestone in the field of industrial machining. Through their tireless efforts in research and development, they have revolutionized the way manufacturers approach their machining processes. With enhanced performance, extended lifespan, and cost-effectiveness, these cutter teeth have proven to be a game-changer for the manufacturing industry. As the demand for improved efficiency and productivity continues to rise, this brand's innovative solutions will undoubtedly play a crucial role in shaping the future of machining.

Excavator Attachments: Tooth Bucket for Improved Digging Performance

Excavation and construction projects have never been easier with the latest innovation in the construction industry - the Tooth Bucket Excavator by a leading construction machinery manufacturer. This powerful and efficient machine is set to revolutionize the way construction projects are carried out, offering increased productivity, precision, and ease of use for operators.The Tooth Bucket Excavator, designed and manufactured by the renowned company, is a game-changer in the construction industry. With its state-of-the-art technology and robust build, this machine is capable of handling even the toughest of excavation tasks with ease. Whether it's digging trenches, clearing debris, or loading materials, this excavator is up for the challenge.One of the key features of the Tooth Bucket Excavator is its advanced tooth bucket attachment, which is specifically designed to improve digging and material handling capabilities. The toothed design of the bucket allows for better penetration into the ground and ensures a secure grip on materials, making it ideal for a wide range of excavation tasks. This means that operators can expect faster and more efficient excavation, leading to increased productivity and cost savings on construction projects.In addition to its powerful performance, the Tooth Bucket Excavator is also equipped with advanced technology to enhance its usability. The intuitive controls and ergonomic design of the machine make it easy for operators to maneuver and operate the excavator with precision and accuracy. This not only improves efficiency but also reduces the risk of operator fatigue, leading to a safer and more comfortable working environment.Furthermore, the Tooth Bucket Excavator is designed with durability and longevity in mind. It is constructed using high-quality materials and components, ensuring that it can withstand the rigors of heavy-duty construction work. This means that construction companies can rely on this machine to deliver consistent performance even in the most demanding working conditions, ultimately leading to a longer service life and reduced maintenance costs.In line with the company's commitment to sustainability, the Tooth Bucket Excavator is also engineered to be fuel-efficient and environmentally friendly. By utilizing advanced engine technology and efficient hydraulics, this excavator minimizes fuel consumption and reduces harmful emissions, making it a responsible choice for construction companies looking to minimize their environmental impact.The company behind the Tooth Bucket Excavator is a global leader in the construction machinery industry, with a proven track record of delivering high-quality and innovative equipment. With decades of experience and expertise, the company has continually pushed the boundaries of technology to provide cutting-edge solutions for the construction sector. Its commitment to excellence and customer satisfaction has earned it a solid reputation as a trusted partner for construction companies worldwide.With the introduction of the Tooth Bucket Excavator, the company is once again demonstrating its dedication to innovation and advancement in the construction industry. This machine is set to raise the bar for excavation equipment, offering unmatched performance, efficiency, and reliability for construction projects of all scales.In conclusion, the Tooth Bucket Excavator by the leading construction machinery manufacturer is a game-changing innovation that is poised to transform the way excavation and construction work is carried out. With its powerful performance, advanced technology, and durability, this excavator is set to become an indispensable asset for construction companies looking to enhance their productivity and efficiency. As the construction industry continues to evolve, the company is at the forefront of driving progress and shaping the future of construction machinery.

Essential Components of an Excavator: A Detailed Look

Parts of the Excavator: A Look into the Components That Make Up the Robust MachineryExcavators are powerful machines that are essential to construction and mining operations. They are capable of performing a wide range of tasks, from digging trenches and foundations to demolishing structures and handling materials. At the heart of these versatile machines are a number of intricate components that work together to ensure optimal performance. In this article, we will take a closer look at some of the key parts that make up the excavator and explore how they contribute to its functionality.First and foremost, the excavator's engine is the powerhouse that drives all of its operations. This component is responsible for generating the necessary power to operate the hydraulic system, which enables the machine to perform its various functions. The engine must be well-maintained and regularly serviced to ensure that it continues to operate at peak performance.The hydraulic system is another crucial part of the excavator, as it is responsible for providing the force and control needed to operate the machine's arm, bucket, and other attachments. This system is made up of a series of hydraulic cylinders, hoses, and pumps that work together to transmit power from the engine to the various components of the excavator. Without a properly functioning hydraulic system, the excavator would be unable to perform the tasks for which it is designed.The arm and boom are two of the most visible components of the excavator, and they are essential for carrying out the machine's digging and lifting operations. The arm is connected to the base of the excavator and can be extended and retracted, while the boom is attached to the arm and is used to raise and lower the attached implements. These components are typically made from high-strength steel to withstand the heavy loads and intense forces that they are subjected to during operation.The bucket is another integral part of the excavator, as it is the primary tool used for digging and scooping up materials. Buckets come in a variety of sizes and shapes to accommodate different tasks, and may also be equipped with teeth or other attachments to improve their performance. It is important that the bucket is properly maintained and replaced when necessary to ensure that it continues to operate effectively.Tracks or wheels are the means by which the excavator moves around the job site. Tracks are commonly used on larger excavators, as they provide better traction and stability on uneven terrain, while wheels are more common on smaller machines. Both tracks and wheels must be regularly inspected and maintained to ensure that they continue to provide reliable performance.In addition to these major components, the excavator also contains a number of smaller parts and systems that are essential for its operation. These include the cab, controls, cooling system, and various safety features. Each of these parts plays a critical role in the overall functionality and safety of the machine, and must be carefully maintained to ensure that the excavator continues to operate safely and efficiently.{Company} is a leading manufacturer of excavators and other heavy construction equipment. With a commitment to quality and innovation, {Company} has developed a reputation for producing reliable and high-performance machines that are designed to meet the needs of the modern construction industry. The company's excavators are built to withstand the rigors of heavy-duty work, and are equipped with the latest technology to improve efficiency and productivity on the job site.In conclusion, excavators are complex machines that rely on a multitude of components to operate effectively. Each of these parts plays a critical role in the overall functionality and performance of the machine, and must be carefully maintained to ensure that the excavator continues to operate safely and efficiently. With the support of a reputable manufacturer like {Company}, customers can be confident in the reliability and durability of their excavator's parts, allowing them to tackle tough jobs with ease.

Innovative Cutting Edge with Teeth - A Game Changer in the Industry

Bolt On Cutting Edge With Teeth is a renowned company in the field of manufacturing and supplying high-quality cutting edge products for various industries. With a history of providing top-notch products and excellent customer service, Bolt On Cutting Edge With Teeth has become a trusted name among its clients.Established in [year], Bolt On Cutting Edge With Teeth has consistently strived to offer innovative solutions for the cutting edge needs of its customers. The company is committed to producing cutting edge products that are not only durable and long-lasting but also efficient and cost-effective. With a team of highly skilled engineers and technicians, Bolt On Cutting Edge With Teeth has been able to develop cutting edge solutions that meet the highest quality standards.The company's cutting edge products are widely used in industries such as construction, mining, agriculture, and road maintenance. Whether it is for excavators, loaders, dozers, or graders, Bolt On Cutting Edge With Teeth has a wide range of cutting edge products to cater to the diverse needs of its clients. These products are designed to withstand the toughest working conditions and deliver exceptional performance.One of the key factors that sets Bolt On Cutting Edge With Teeth apart from its competitors is its focus on continuous innovation and product development. The company invests heavily in research and development to stay ahead of the curve and bring cutting edge solutions to the market. This dedication to innovation has enabled Bolt On Cutting Edge With Teeth to introduce cutting edge products that offer improved efficiency, longevity, and performance.In addition to its cutting edge products, Bolt On Cutting Edge With Teeth also offers a range of services to its clients, including custom fabrication and installation. The company's team of experts works closely with clients to understand their specific requirements and provide tailored solutions that meet their needs. Whether it is a standard cutting edge product or a customized solution, Bolt On Cutting Edge With Teeth strives to deliver the highest level of satisfaction to its customers.With a strong commitment to quality and customer satisfaction, Bolt On Cutting Edge With Teeth has built a solid reputation in the industry. The company's cutting edge products are trusted by leading businesses and organizations around the world. Its commitment to excellence and innovation has helped Bolt On Cutting Edge With Teeth to become a preferred choice for cutting edge solutions.Furthermore, Bolt On Cutting Edge With Teeth prides itself on its excellent customer service and support. The company's team of professionals is always available to assist clients with their cutting edge needs, whether it is product inquiries, technical support, or after-sales service. This dedication to customer satisfaction has helped Bolt On Cutting Edge With Teeth to build long-lasting relationships with its clients.As Bolt On Cutting Edge With Teeth continues to grow and expand its product range, the company remains committed to its core values of quality, innovation, and customer satisfaction. With a focus on providing cutting edge solutions that deliver exceptional results, Bolt On Cutting Edge With Teeth is poised to maintain its position as a leader in the cutting edge industry.In conclusion, Bolt On Cutting Edge With Teeth is a company that is synonymous with quality, innovation, and excellence in the cutting edge industry. With its unwavering commitment to providing top-notch products and exceptional customer service, Bolt On Cutting Edge With Teeth has established itself as a trusted partner for cutting edge solutions. As the company continues to push the boundaries of innovation, it is set to solidify its position as a leader in the industry for years to come.

Unveiling the Key Role of Excavator Pins in Construction Projects

Excavator Pins: Revolutionizing Construction with Precision and Durability[Company Name], a renowned leader in construction machinery, has recently introduced a groundbreaking innovation in the field of excavators with their latest release of Excavator Pins. Designed to provide unparalleled precision, durability, and efficiency, these new Excavator Pins are set to revolutionize the construction industry.With a mission to constantly push the boundaries of technology and engineering, [Company Name] has invested extensive research and development into creating Excavator Pins that are truly cutting-edge. These pins are specially engineered to ensure enhanced performance, increased productivity, and extended machine longevity.The Excavator Pins manufactured by [Company Name] boast exceptional precision, enabling smooth and seamless operations on construction sites. The perfect fit achieved by these pins minimizes any unwanted vibrations or movements, ensuring utmost accuracy and control during various excavating operations. This precision ultimately leads to improved productivity and reduced downtime, saving construction companies valuable time and resources.Durability is another key feature of the Excavator Pins from [Company Name]. The company has employed advanced materials and manufacturing techniques to produce pins that can withstand even the harshest conditions. Whether it's heavy loads, extreme temperatures, or challenging terrains, these pins are built to last. By minimizing maintenance requirements and increasing the lifespan of their excavators, [Company Name] aims to provide their clients with a cost-effective and reliable solution.In addition to their superior performance and durability, the Excavator Pins are also designed to be easily replaceable. By utilizing innovative locking mechanisms, [Company Name] has simplified the process of swapping out pins, reducing downtime and enhancing efficiency on the construction site. This efficient and user-friendly design ensures that the excavators equipped with these pins can operate at their maximum capacity for extended periods, further boosting productivity and reducing costs.The Excavator Pins from [Company Name] have already garnered significant attention in the construction industry. Several prominent construction companies have applauded the innovation and performance of these pins, solidifying [Company Name]'s position as the leader in the market. The company's unwavering commitment to delivering high-quality machinery has earned them the trust and loyalty of customers worldwide.Furthermore, [Company Name] has a strong focus on sustainability and environmental responsibility. The materials used in manufacturing the Excavator Pins are carefully selected to minimize environmental impact without compromising on performance. By investing in these environmentally conscious pins, construction companies can contribute to a greener future while benefiting from their exceptional functionality.Moreover, [Company Name] offers comprehensive customer support to ensure that their clients get the most out of their Excavator Pins. Their team of highly skilled technicians is readily available to provide assistance, perform regular maintenance, and address any concerns that may arise. By prioritizing customer satisfaction, [Company Name] aims to foster long-term relationships and establish itself as a trusted partner in the construction industry.In conclusion, the introduction of Excavator Pins by [Company Name] is set to revolutionize the construction industry. With their exceptional precision, durability, and efficiency, these pins will enhance productivity, reduce downtime, and increase cost-effectiveness for construction companies worldwide. By embracing this groundbreaking innovation, construction professionals can take their operations to new heights, confident in the superior performance and reliability of [Company Name]'s Excavator Pins.

Efficient Mini Excavator Blade Unveiled: A Game-Changer for Construction Sites

Title: Innovative Mini Excavator Blade Revolutionizes Construction IndustryIntroduction:The construction industry has witnessed a groundbreaking transformation with the introduction of the state-of-the-art Mini Excavator Blade (remove brand name), manufactured by an innovative and cutting-edge company (). This revolutionary equipment promises to enhance efficiency, productivity, and precision in excavation projects, revolutionizing the way construction professionals operate.Groundbreaking Features and Functionality:The Mini Excavator Blade boasts several groundbreaking features that set it apart from its competitors, cementing its position as a game-changer in the construction industry. This state-of-the-art equipment combines power, versatility, and advanced technology to tackle excavation tasks with unmatched efficiency.1. Advanced Hydraulic System: With an intricate hydraulic system, the Mini Excavator Blade delivers exceptional power and precision, enabling operators to effortlessly maneuver in tight spaces, such as urban construction sites or confined areas. The responsive hydraulic controls provide smooth and accurate operation, reducing the chances of damage to surrounding structures during excavation.2. Intelligent Control Panel: Equipped with an intuitive control panel, operators can easily manage various functions and optimize performance. The ergonomic design and user-friendly interface allow for seamless operation, minimizing downtime and enhancing overall productivity.3. Versatile Blade Attachments: The Mini Excavator Blade offers a range of interchangeable blade attachments, allowing operators to customize the equipment according to the specific project requirements. Whether for grading, trenching, scooping, or backfilling, the blade attachments significantly increase versatility, eliminating the need for multiple machines on-site.4. Compact Size, Powerful Performance: The Mini Excavator Blade's compact design enables it to navigate through narrow spaces and work efficiently in restricted areas without compromising on power. Despite its small stature, it delivers formidable performance, making it the ideal choice for a broad range of excavation tasks.Industry-Leading Safety Features:Safety is paramount in the construction industry, and the Mini Excavator Blade prioritizes this aspect by incorporating advanced safety features. The equipment is designed with reinforced operator cabins that offer enhanced protection against debris, falling objects, and other potential hazards. Additionally, the blade attachments are engineered to minimize the risk of accidental damage or injury during operation.Enhanced Efficiency and Reduced Costs:The introduction of the Mini Excavator Blade by () brings numerous benefits to construction companies, aiding them in not only completing projects more efficiently but also reducing overall costs.1. Time-Saving: The Mini Excavator Blade's superior functionality and maneuverability significantly reduce excavation time, allowing for faster project completion. Its ability to adapt to various terrains and soil types ensures continuous progress, eliminating downtime and optimizing work schedules.2. Cost-Effective: By combining multiple functions and eliminating the need for additional machines, the Mini Excavator Blade proves to be a cost-effective solution for construction projects. The reduction in fuel consumption, maintenance expenses, and manpower requirements contribute to significant overall savings.Market Impact and Future Prospects:The Mini Excavator Blade's introduction into the construction industry marks a turning point, providing professionals with a comprehensive excavation solution that surpasses traditional methods in terms of efficiency and precision. Its unique features and versatility make it a preferred choice for contractors and project managers worldwide.With a growing demand for sustainable and efficient construction practices, the Mini Excavator Blade (remove brand name) is set to experience exponential growth. The company () is committed to continuous innovation and market adaptation to further enhance the equipment's capabilities, ensuring it remains at the forefront of the industry.Conclusion:The revolutionary Mini Excavator Blade, developed by (), is transforming the construction industry by offering unmatched efficiency, enhanced versatility, and advanced safety features. With its compact size and powerful performance, this state-of-the-art equipment is heralding a new era in excavation practices. As the demand for more sustainable and efficient construction methods continues to rise, the Mini Excavator Blade is poised to shape the future of the industry, delivering greater productivity, improved cost-effectiveness, and exceptional results.

How a Grading Blade Can Help Level Your Mini Excavator

Mini Excavator Grading Blade: Revolutionizing Precision and Efficiency in Construction[City], [Date] - Construction has always been an industry that demands precision, efficiency, and innovation. As technology advances, so do the tools and equipment used in this field. And now, with the advent of the Mini Excavator Grading Blade, the construction sector is poised to witness a new level of productivity and accuracy.Developed by [Company Name], a leading manufacturer of heavy machinery and equipment, the Mini Excavator Grading Blade is set to revolutionize the way construction projects are carried out. With its cutting-edge features and unparalleled performance, this remarkable tool is designed to streamline grading, leveling, and excavation tasks, making them faster, easier, and more precise than ever before.The Mini Excavator Grading Blade is specifically engineered for use with mini excavators, making it the ideal choice for small to medium-scale construction projects. It is a versatile attachment, capable of tackling a wide range of tasks including grading driveways, leveling landscapes, digging trenches, and more. With its compact design, it allows operators to maneuver through tight spaces and reach areas that are inaccessible to larger machinery.One of the key features that sets the Mini Excavator Grading Blade apart from other attachments is its advanced hydraulic system. Equipped with state-of-the-art technology, this system ensures smooth and precise blade movements, enhancing control and accuracy during operation. Furthermore, the hydraulic system allows for easy adjustments, allowing operators to fine-tune the grading blade to meet specific project requirements.The grading blade itself is made from high-quality materials, ensuring durability and longevity even when subjected to heavy use. Its robust construction makes it suitable for various terrains, from soft soils to rocky surfaces. This versatility gives construction professionals the confidence to tackle any project, knowing that they have a reliable tool at their disposal.In addition to its outstanding performance, the Mini Excavator Grading Blade offers a user-friendly experience. The attachment can be easily installed on mini excavators, saving precious time and effort. Once in place, the intuitive controls and ergonomic design allow operators to efficiently navigate the blade, minimizing operator fatigue and maximizing productivity.Furthermore, safety is a top priority in the construction industry. The Mini Excavator Grading Blade incorporates several safety features to protect both operators and the surrounding environment. The attachment is equipped with a blade lock system, which securely holds the blade when not in use, preventing accidental movement and potential injuries. Additionally, the grading blade is fitted with reflective markers, enhancing visibility and reducing the risk of accidents on-site.With the arrival of the Mini Excavator Grading Blade, construction companies can expect significant improvements in their operations. The time and labor savings offered by this innovative tool translate into increased productivity and more efficient project completion. Moreover, the enhanced precision and control provided by the attachment result in superior quality workmanship, ultimately leading to increased client satisfaction.[Company Name], the manufacturer behind this groundbreaking invention, has been a renowned player in the heavy machinery industry for over a decade. With a strong commitment to driving innovation and meeting the evolving needs of their clients, the company has consistently delivered cutting-edge solutions that push the boundaries of construction equipment. The Mini Excavator Grading Blade is yet another testament to their dedication to excellence.In conclusion, the introduction of the Mini Excavator Grading Blade marks a significant milestone in the construction industry. Its exceptional performance, advanced features, and user-friendly design make it an invaluable tool for construction professionals across various projects. As technology continues to redefine the sector, innovations like the Mini Excavator Grading Blade are reinventing the way construction projects are carried out, bringing greater precision, efficiency, and quality to the field.

Effective Ways to Enhance Efficiency for Excavation Projects with Side Cutter Buckets

A new excavator attachment, the side cutter bucket, is making a splash in the construction industry. Introducing a revolutionary design, this bucket is perfect for working in tight spaces and providing precision digging capabilities. It is quickly becoming a must-have attachment for those in the industry.Unlike traditional buckets, the side cutter bucket features a unique design that enables it to cut through soil and rock with ease. Its V-shaped cutting edges make it ideal for use in tight areas where traditional buckets can be too cumbersome. This excavator attachment has been specifically designed for small and medium-sized excavation projects, offering exceptional versatility and performance.One of the key benefits of this excavator attachment is its precision. The side cutter bucket is designed for accuracy, making it ideal for working on jobs where precision is required. The V-shaped cutting edges allow operators to operate the bucket with precision, which reduces the time and cost of excavation projects.The side cutter bucket is also highly durable. It is made using high-quality materials that ensure long-lasting performance. Its design is such that it is easy to maintain and efficient in terms of fuel consumption, making it not only a great choice for excavation projects but also a cost-effective one.The manufacturer of this attachment is a leading construction equipment manufacturer. With years of experience in the industry, they are trusted to provide high-quality equipment that meets the needs of construction professionals. They have built a reputation for providing cutting-edge technology that helps contractors complete projects quickly and efficiently.Their commitment to quality is evident in their manufacturing process. Each side cutter bucket is made using state-of-the-art machinery that ensures perfect precision. The buckets undergo rigorous testing to ensure that they meet the highest standards of quality and performance.In addition to their commitment to quality, the manufacturer also provides top-notch customer service. They offer comprehensive support throughout the sales process to help customers choose the best equipment for their project requirements. They also provide training and support after the sale to ensure that customers get the most out of their purchase.Construction professionals have already started to include the side cutter bucket in their arsenal of equipment. The attachment is gaining popularity for its versatility and precision, making it a valuable addition to any excavation project. Contractors who have used the side cutter bucket have reported that it has helped them save time, reduce costs, and increase efficiency.The side cutter bucket is an excellent example of innovative technology being integrated into the construction industry. Its V-shaped cutting edges, precision, and durability make it a valuable asset for contractors who are looking to expand their excavation capabilities. With its excellent performance, it is set to revolutionize the way excavators are used in the industry.In conclusion, the side cutter bucket is a versatile and efficient excavator attachment that is gaining popularity in the construction industry. Its unique design and cutting-edge technology make it the perfect solution for small and medium-sized excavation projects. With its precision and durability, it is set to become one of the most essential pieces of equipment for contractors who are looking to maximize their efficiency and productivity on the job site. The manufacturer's commitment to quality and customer service further cements their position as a leader in the industry, ensuring that their customers receive the best possible products and support.

Unveiling the World's Biggest Bucket Wheel Excavator for Unprecedented Mining Operations

Largest Bucket Wheel Excavator Sets New Industry StandardIn a groundbreaking development, a renowned construction equipment manufacturer has unveiled the largest bucket wheel excavator ever created. With its impressive size and cutting-edge technology, this massive excavator is set to revolutionize the mining and construction industry.Designed and developed by a leading company in heavy equipment manufacturing, this gargantuan bucket wheel excavator no longer bears a brand name. However, its technical expertise is unquestionable, with a successful track record of producing high-quality and innovative machinery.Weighing in at an astonishing 14,000 tons, this bucket wheel excavator is a true giant of the industry. Its sheer size and power make it an optimal choice for large-scale mining projects and complex construction operations. With a total height of over 80 meters and a length of 240 meters, this colossal machine is a true engineering marvel.The bucket wheel excavator works by rotating a large wheel with multiple buckets attached to it. As the wheel rotates, the buckets scoop up earth or other materials and carry them to a conveyor belt, which then transports the material for processing or removal. This efficient process allows for the excavation of vast quantities of materials in a short period.One of the key features of this new excavator is its state-of-the-art technology. Equipped with advanced automation systems and artificial intelligence, the operator's job is made easier and safer. The excavator's built-in sensors and cameras provide real-time data and imaging, allowing for precise control and monitoring during operation. This reduces the risk of accidents and enhances overall productivity.The excavator's efficiency goes beyond its cutting-edge technology. Its unique design ensures minimal environmental impact, with reduced noise levels and lower energy consumption compared to previous models. With environmental sustainability becoming increasingly crucial in the industry, this excavator sets a new standard in balancing productivity and ecological responsibility.In addition to its size and advanced features, this bucket wheel excavator boasts a robust and durable construction. Constructed with high-grade materials and meticulous craftsmanship, it was built to withstand the harshest conditions and deliver exceptional performance over an extended lifespan. Its reliability minimizes downtime, thereby maximizing productivity and profitability for construction companies and mining operations.Furthermore, this bucket wheel excavator is highly adaptable, ensuring versatility in its application across various projects. Whether it's in open-pit mining operations, large-scale construction projects, or even in the petroleum and gas industry for pipeline installation, this excavator proves capable and efficient in all its endeavors.The unveiling of the largest bucket wheel excavator marks a significant milestone in the construction and mining industry. It showcases the commitment of the company to push boundaries and deliver groundbreaking equipment that enhances productivity, reduces environmental impact, and ensures the safety of workers.As this mammoth excavator hits the market, construction and mining companies worldwide eagerly await its deployment in their projects. The sheer magnitude and advanced technology of this machine are expected to set new benchmarks for performance and redefine the capabilities of bucket wheel excavators in the industry.The yet-to-be-named largest bucket wheel excavator has already garnered attention and admiration globally. With its unparalleled size, cutting-edge technology, and commitment to sustainability, it is poised to become an indispensable tool for the construction and mining sector.As the unveiling of this extraordinary bucket wheel excavator demonstrates, the company responsible for its creation continues to establish itself as a pioneer in the heavy equipment manufacturing industry. Thanks to their relentless pursuit of innovation, construction and mining professionals can now look forward to a new era of productivity and efficiency, propelled by this remarkable piece of engineering.

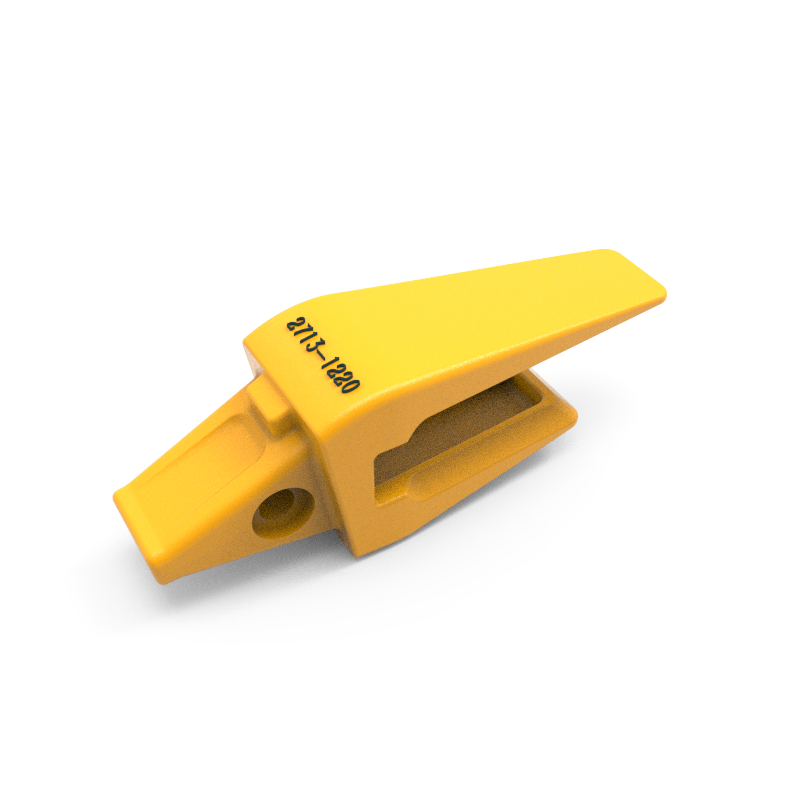

Top-rated Bucket Teeth for Various Equipment Models

Kubota Excavator Attachment Manufacturer Introduces Cutting-Edge Bucket TeethAs a leading manufacturer of excavator attachments, {Company Name} is proud to introduce our latest innovation in the construction industry - the new and improved bucket teeth for Kubota excavators. These state-of-the-art bucket teeth are designed to provide maximum durability and effectiveness, allowing construction professionals to complete their projects with ease and efficiency.With a focus on quality and performance, {Company Name} has dedicated extensive research and development to creating bucket teeth that exceed industry standards. Our team of engineers has utilized the latest technology and materials to ensure that these bucket teeth are built to withstand the harshest working conditions without compromising on performance.The new bucket teeth are specifically designed to fit Kubota excavators, providing a perfect and secure fit for seamless operation. With a focus on precision engineering, {Company Name}'s bucket teeth are expertly crafted to ensure a tight grip and minimal wear, allowing for greater productivity and cost savings in the long run.One of the key features of the new bucket teeth is their enhanced durability. Constructed from high-quality, heat-treated steel, these bucket teeth are built to withstand heavy-duty use, making them suitable for a wide range of excavation and construction applications. The superior strength and resistance to abrasion ensure that these bucket teeth can tackle even the toughest materials without wearing down quickly.In addition to their durability, {Company Name}'s new bucket teeth are also designed for maximum effectiveness. The unique design of the teeth ensures efficient penetration and precise cutting, allowing for smooth and efficient excavation. This not only improves productivity on the job site but also reduces fuel consumption and overall operating costs.Furthermore, {Company Name} has placed a strong emphasis on ease of maintenance and replacement. The new bucket teeth are designed for easy installation and quick replacement, minimizing downtime and maximizing uptime for construction professionals. This ensures that operators can keep their Kubota excavators running smoothly without any unnecessary delays.{Company Name} takes pride in providing superior products that meet the needs of the modern construction industry. By continually investing in research and development, we strive to stay ahead of the curve and offer innovative solutions that enhance the performance and efficiency of our customers' machinery.The introduction of the new bucket teeth for Kubota excavators is a testament to {Company Name}'s commitment to quality and customer satisfaction. With these cutting-edge bucket teeth, construction professionals can expect improved durability, efficiency, and performance, ultimately leading to enhanced productivity and profitability on the job site.As {Company Name} continues to push the boundaries of innovation in the construction industry, we remain dedicated to providing our customers with the best solutions for their excavator attachment needs. The new bucket teeth for Kubota excavators are a testament to our ongoing commitment to excellence, and we are excited to see the positive impact they will have on construction projects around the world.