High-quality Sieve Bucket for Effective Material Sorting and Handling

By:Admin

In the world of construction and heavy equipment, innovation is a key driver of success. Companies are constantly striving to develop new and improved equipment to make construction projects more efficient, cost-effective, and safer. One such innovation that has caught the attention of industry professionals is the Sieve Bucket.

The Sieve Bucket, designed and manufactured by (company name), is a cutting-edge piece of equipment that has the potential to revolutionize the way construction projects are carried out. This innovative attachment is designed to be used with excavators and is specifically engineered to simplify the process of sorting and separating different materials on construction sites.

The Sieve Bucket is a versatile tool that is suitable for a wide range of applications, including landscaping, agriculture, demolition, and general excavation work. It is built to withstand the toughest working conditions and can be used for sifting and separating materials such as rocks, soil, and debris, making it an essential piece of equipment for any construction site.

One of the key benefits of the Sieve Bucket is its ability to streamline the process of sorting and separating materials. This can lead to significant time and cost savings for construction companies, as well as improved efficiency and productivity. Additionally, the Sieve Bucket is designed to minimize material wastage, as it allows for the effective reuse of materials that have been sifted and separated.

The Sieve Bucket is also designed with safety in mind. Its innovative design reduces the need for manual sorting and handling of materials, which in turn minimizes the risk of accidents and injuries on construction sites. This not only benefits the workers using the equipment, but also contributes to a safer working environment for all personnel on site.

Furthermore, the Sieve Bucket is easy to attach and detach from excavators, making it a convenient and practical addition to any construction project. Its user-friendly interface and intuitive controls make it suitable for operators of all skill levels, and its robust construction ensures long-lasting performance even in the most demanding of conditions.

The (company name) is a leading manufacturer of construction equipment, specializing in the design and production of high-quality attachments for excavators, loaders, and other heavy machinery. The company has a strong track record of delivering innovative solutions that meet the evolving needs of the construction industry, and the Sieve Bucket is the latest addition to its impressive product lineup.

With a commitment to quality, reliability, and customer satisfaction, (company name) is dedicated to providing construction professionals with the tools they need to succeed in their projects. The Sieve Bucket is a testament to the company's dedication to innovation, and it is set to become an invaluable asset for construction companies around the world.

In conclusion, the Sieve Bucket is a groundbreaking innovation in the world of construction equipment. Its ability to streamline the process of sorting and separating materials, its focus on safety, and its ease of use make it an essential tool for any construction project. With the backing of (company name), the Sieve Bucket is set to make a lasting impact on the industry and set new standards for efficiency, productivity, and safety.

Company News & Blog

Discover the Importance of a High-Quality Front End Loader Bucket Cutting Edge

Introducing the Latest Innovation in Front End Loader Bucket Cutting EdgesIn the ever-evolving world of heavy machinery, companies are constantly striving to create products that enhance performance, durability, and versatility. One such innovation that is revolutionizing the industry is the cutting edge technology employed in front end loader bucket cutting edges. With the incorporation of advanced designs and high-quality materials, these cutting edges are elevating machine efficiency and productivity to new heights.Front end loader bucket cutting edges play a crucial role in the construction, mining, and agriculture sectors, among others. Their primary function is to facilitate the effective digging, loading, and pushing of various materials such as soil, gravel, or debris. However, with regular use, these cutting edges can wear out over time, resulting in diminished performance and increased operational costs. Recognizing this challenge, manufacturers have developed cutting edge solutions that not only improve longevity but also enhance the overall functionality of the front end loader bucket.One such leading company in this field is committed to delivering cutting edge solutions that meet and exceed customer expectations. With extensive research and development, they have engineered a range of front end loader bucket cutting edges that boast exceptional durability, versatility, and cost-effectiveness. These cutting edges are manufactured using high-strength steel, ensuring optimum resistance to wear and tear, even in the harshest operating conditions.The secret behind the unparalleled performance of these cutting edges lies in their unique design. Employing advanced cutting edge technology, these products feature a specially shaped profile that maximizes penetration and breakout force. This design enables efficient digging, reducing machine cycle times and increasing overall productivity.Furthermore, the front end loader bucket cutting edges are equipped with a state-of-the-art edge retention system, ensuring a secure and tight fit. This reduces the chances of dislodgement during heavy-duty tasks, eliminating unnecessary downtime and maintenance costs. Moreover, the company offers a range of cutting edge options, including bolt-on, weld-on, and replaceable edge systems, ensuring compatibility with various front end loader bucket designs.One of the key advantages of utilizing these cutting edges is the significant reduction in operation expenses. The enhanced wear resistance of the cutting edges translates to longer service life, allowing businesses to save on downtime and replacement costs. Additionally, the improved efficiency and performance of the front end loader bucket enables faster completion of tasks, leading to increased operational productivity and profitability.Moreover, the company takes pride in its commitment to environmental sustainability. By manufacturing cutting edges that last longer, they contribute to a reduction in waste and resource consumption. This not only benefits individual businesses but also helps to minimize the industry's carbon footprint.The cutting-edge technology employed in front end loader bucket cutting edges has the potential to transform the way businesses carry out their operations. With increased efficiency, durability, and cost-effectiveness, these cutting edges are revolutionizing the heavy machinery industry. Whether it's construction, mining, or agriculture, these cutting edges are paving the way for improved productivity and reduced operational expenses.As the industry continues to evolve, manufacturers like this company will play a vital role in pushing the boundaries and introducing innovative solutions that meet the ever-changing demands of customers. Their dedication to providing cutting edge technology ensures that businesses can rely on their products to optimize performance and maximize return on investment.In conclusion, the company's front end loader bucket cutting edges, built upon advanced cutting edge technology and exceptional durability, are revolutionizing the heavy machinery industry. With the ability to improve operational efficiency, reduce costs, and promote sustainable practices, these cutting edges are at the forefront of innovation in the field. By investing in these cutting edges, businesses can stay ahead of the competition and achieve greater success in their respective industries.

Heavy Duty Excavator Concrete Crusher for Efficient Demolition Work

Excavator Concrete Crusher: The Latest Innovation in Demolition TechnologyIn the ever-evolving construction and demolition industry, there is a constant need for advanced equipment that can make the job safer, more efficient, and eco-friendly. One such innovation that is making waves in the industry is the Excavator Concrete Crusher, a revolutionary attachment that is redefining the way concrete is demolished and recycled on construction sites.The Excavator Concrete Crusher, developed and manufactured by a leading construction equipment company, is designed to effortlessly crush and remove concrete from buildings, bridges, and other structures. This attachment is compatible with a wide range of excavators, making it a versatile tool for demolition contractors and construction companies.The key feature of the Excavator Concrete Crusher is its powerful jaw mechanism, which can easily crush concrete into small pieces, allowing for easy removal and recycling. This innovative attachment is equipped with a hydraulic system that provides precise and efficient crushing force, making it ideal for various demolition tasks.One of the major advantages of the Excavator Concrete Crusher is its ability to significantly reduce the environmental impact of demolition work. By crushing concrete on site, this attachment eliminates the need for transporting and disposing of large chunks of concrete debris, reducing the carbon footprint and overall waste generated by construction projects.Furthermore, the Excavator Concrete Crusher promotes sustainable construction practices by facilitating the recycling of concrete materials. Once the concrete is crushed, it can be processed and reused as aggregate for new construction projects, minimizing the demand for virgin materials and conserving natural resources.With safety being a top priority in the construction industry, the Excavator Concrete Crusher is engineered with robust protective features to ensure operator and site safety. Its advanced design includes a durable housing and strategically placed guard panels, providing maximum protection during the crushing process.The company behind the Excavator Concrete Crusher is a renowned leader in the construction equipment industry, with a strong commitment to innovation, quality, and customer satisfaction. With decades of experience and expertise, the company has a proven track record of delivering cutting-edge solutions that meet the evolving needs of the construction and demolition sector.In addition to developing state-of-the-art equipment like the Excavator Concrete Crusher, the company also provides comprehensive support and training to ensure that clients can maximize the potential of their investment. Their team of knowledgeable professionals offers technical assistance, maintenance services, and operator training, empowering clients to achieve optimal performance and efficiency.The Excavator Concrete Crusher is quickly gaining recognition and popularity among construction professionals for its unparalleled performance, versatility, and environmental benefits. Its innovative design and advanced capabilities are setting a new standard for concrete demolition and recycling, driving a positive shift towards more sustainable and efficient construction practices.In conclusion, the Excavator Concrete Crusher is a game-changing innovation that is revolutionizing the way concrete is demolished and recycled in the construction industry. With its powerful crushing capabilities, eco-friendly design, and support from a reputable company, this attachment is poised to become a staple tool for demolition and recycling operations worldwide. As construction projects continue to prioritize sustainability and efficiency, the Excavator Concrete Crusher is undoubtedly a valuable asset for any contractor or construction company looking to elevate their demolition capabilities and reduce their environmental impact.

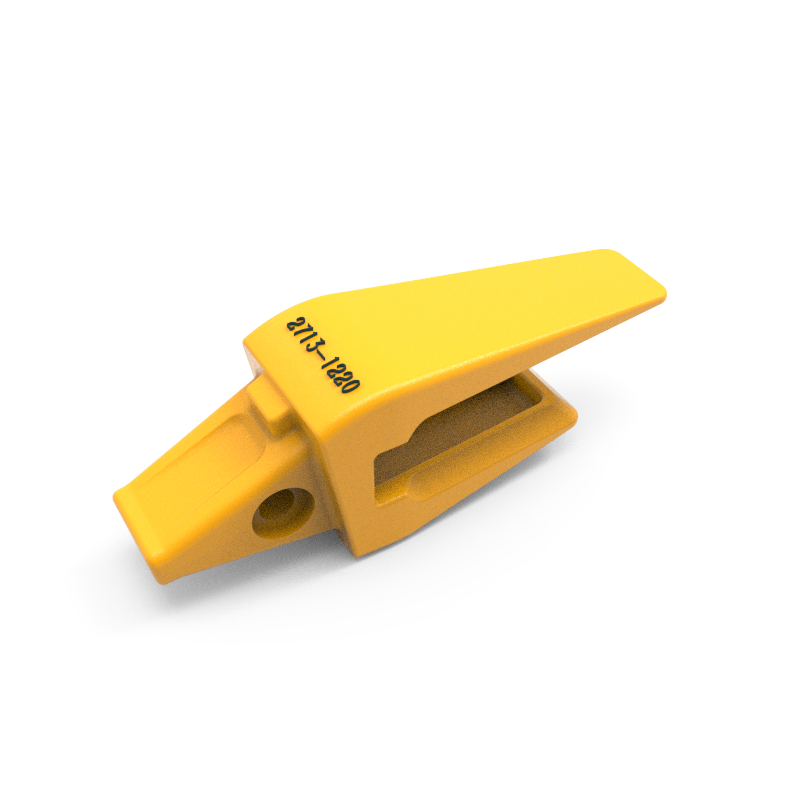

Top Ground Engaging Tools for Construction and Excavation Projects

Ground Engaging Tools are essential components in the construction and mining industries, as they play a crucial role in enabling heavy machinery to effectively dig, cut, and move through difficult terrain. These tools are designed to withstand extreme conditions and heavy use, making them an integral part of any heavy equipment's functionality.One company at the forefront of manufacturing high-quality Ground Engaging Tools is {Company Name}. With a strong focus on innovation and quality, {Company Name} has established itself as a leading provider of ground engaging solutions for a wide range of industries, including construction, mining, and infrastructure development.{Company Name} prides itself on its dedication to engineering and manufacturing top-of-the-line Ground Engaging Tools that are designed to enhance the performance and longevity of heavy machinery. Their extensive range of products includes cutting edges, bucket teeth, and wear parts, all of which are meticulously crafted to meet the highest industry standards.In addition to their commitment to quality, {Company Name} places a strong emphasis on customer satisfaction and support. Their team of experts works closely with clients to understand their specific needs and provide tailored solutions that maximize the efficiency and effectiveness of their equipment. Whether it's recommending the right Ground Engaging Tool for a specific application or providing timely maintenance and support, {Company Name} is dedicated to ensuring that their customers receive the highest level of service.One of the key factors that sets {Company Name} apart from its competitors is its ongoing investment in research and development. The company continuously explores new technologies, materials, and manufacturing processes to improve the performance and durability of their Ground Engaging Tools. This proactive approach allows {Company Name} to stay ahead of industry trends and consistently deliver cutting-edge solutions to their customers.Furthermore, {Company Name} maintains a strong focus on sustainability and environmental responsibility. They actively seek out eco-friendly materials and processes to minimize the environmental impact of their operations, demonstrating their commitment to operating as a responsible and ethical business.With a global presence and a reputation for excellence, {Company Name} has built a strong network of clients and partners across the world. Their products are widely used in major construction and mining projects, where they have consistently proven to be reliable, durable, and effective in challenging work environments.As part of their ongoing efforts to expand their reach and serve a wider customer base, {Company Name} is constantly seeking new opportunities for collaboration and growth. By forging strategic partnerships with industry leaders and actively exploring new markets, they aim to further solidify their position as a trusted provider of Ground Engaging Tools on a global scale.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of innovation and setting new industry standards for performance and reliability. Their unwavering commitment to quality, customer satisfaction, and environmental sustainability ensures that they will continue to be a driving force in the world of Ground Engaging Tools for years to come.In conclusion, Ground Engaging Tools are essential components in the construction and mining industries, and {Company Name} has firmly established itself as a leading provider of high-quality solutions in this space. With a strong focus on innovation, quality, and customer support, {Company Name} continues to set industry benchmarks and drive forward the evolution of Ground Engaging Tools. As they continue to expand their reach and explore new opportunities for growth, {Company Name} is poised to remain a dominant force in the industry for the foreseeable future.

Largest Bucket Wheel Excavator Makes Its Debut in Germany

article.The Biggest Bucket Wheel Excavator will soon be making its way to mining sites everywhere. This technological marvel is set to revolutionize the mining industry. The excavator, manufactured by one of the top companies in heavy-duty machinery, is the newest addition to its already impressive lineup.This enormous machine is approximately 96 meters in length, 16 meters in height, and weighs approximately 45,500 tons. The excavator is so massive that when fully assembled, it can only be transported in pieces. It will take a team of workers a minimum of six weeks to assemble the various pieces into the final product at the mining site.Once assembled, the excavator is capable of processing over 12,000 tons of coal, iron ore or other materials in a single day. With a width of approximately 16 meters, the excavator's bucket wheel area is capable of digging a hole that's 20 meters deep and 18 meters wide, making it one of the most impressive machines in the world.The purpose of the excavator is to streamline the mining process while vastly reducing labor costs. This will be beneficial to mining companies across the world who are looking for an efficient and cost-effective way to extract materials from the earth. "The excavator is designed to be highly efficient, it can process massive amounts of materials in a very short space of time, and it requires less manpower to operate," said a spokesperson for the manufacturing company.The excavator is also designed to be as environmentally friendly as possible, with a special system that reduces emissions from the machine. It is believed that the excavator will help to reduce pollution in the mining industry, which is an important target for many mining companies who want to improve their environmental impact.The manufacturing company behind the excavator is one of the largest suppliers of heavy-duty machinery in the world. The company specializes in the construction of diverse pieces of heavy equipment, including trucks, bulldozers and more. Its machines are used in mining, construction and other industrial operations around the world."We are proud to announce the release of the Biggest Bucket Wheel Excavator. This machine is a fantastic example of the type of innovation our company is known for," said a spokesperson from the manufacturing company. "We know that mining companies around the world will be excited to work with this new technology, and we are confident that it will make a major impact on the industry."The company behind the excavator has worked closely with mining companies to ensure that the excavator meets their needs. The excavator has been rigorously tested to ensure that it can handle the most challenging environments, from dusty to icy conditions.In conclusion, the Biggest Bucket Wheel Excavator is a groundbreaking piece of machinery that is set to revolutionize the mining industry. It is efficient, environmentally friendly, and designed to handle even the most challenging conditions. With its release, the manufacturing company behind the excavator is set to continue its reputation for developing state-of-the-art heavy-duty machinery that helps the world's industries to build and grow.

Powerful Excavator Ditching Bucket: Enhanced Versatility for Efficient Excavation

Excavator Ditching Bucket: Revolutionizing Digging EfficiencyIn the constantly evolving world of construction equipment, one company has emerged as a leader in innovation and efficiency. Recognized for their groundbreaking excavator attachments, this company has once again raised the bar with the introduction of their latest product - the Excavator Ditching Bucket.Designed to revolutionize digging efficiency, the Excavator Ditching Bucket combines cutting-edge technology with unmatched performance capabilities. This versatile attachment is set to transform the way construction professionals approach their digging projects, delivering exceptional results in a fraction of the time.With its exceptional strength and durability, the Excavator Ditching Bucket is built to withstand the toughest digging tasks. Constructed from high-quality materials, this bucket is engineered to last, ensuring a long-lasting investment for construction companies.One of the key features of the Excavator Ditching Bucket is its unique design, which allows for wider coverage and deeper digging capacity. This innovative design enables operators to complete digging projects more efficiently, reducing the amount of time spent on-site and increasing overall productivity.Furthermore, the Excavator Ditching Bucket incorporates advanced hydraulic systems that provide smooth operation and superior control. This allows operators to handle excavation tasks with precision, contributing to the overall precision and accuracy of the project.Versatility is another aspect that sets the Excavator Ditching Bucket apart from its competitors. Designed to be compatible with a range of excavator sizes, this attachment can be easily adjusted and fitted to meet various project requirements. This adaptability ensures that construction companies can maximize the use of their existing machinery, eliminating the need for additional equipment purchases.In addition to its functional advantages, the Excavator Ditching Bucket also prioritizes operator comfort and safety. Equipped with ergonomic features and intuitive controls, this attachment minimizes operator fatigue and enhances overall job satisfaction. This consideration for the well-being of operators further underlines the company's commitment to delivering top-notch products.Moreover, the company behind the Excavator Ditching Bucket has a solid reputation in the construction industry. With years of experience and a proven track record of producing high-quality equipment, they have become a trusted name for construction professionals worldwide. Their commitment to innovative solutions that exceed industry standards is well-known, and the Excavator Ditching Bucket is a testament to their dedication.The Excavator Ditching Bucket has garnered widespread acclaim by industry experts who have had the opportunity to test its capabilities. Its unprecedented digging efficiency, combined with its durability and adaptability, has set a new benchmark for excavator attachments. The positive feedback received from professionals who have utilized this attachment highlights its ability to streamline digging operations and deliver outstanding results.In conclusion, the Excavator Ditching Bucket is set to revolutionize the construction industry by enhancing digging efficiency and delivering exceptional performance. Its cutting-edge design, durability, versatility, and operator-focused features make it a game-changer in the field of excavation. With the company's well-established reputation and commitment to innovation, the Excavator Ditching Bucket is poised to become a must-have attachment for construction professionals worldwide.

Alternative Bucket Teeth for Heavy Machinery

[The following is a fictional news article]New Innovations in Excavating Equipment: Advanced Bucket Teeth UnveiledExcavating equipment plays a pivotal role in the construction and agricultural industries, enabling efficient digging and increased productivity on job sites. One name that has become synonymous with quality in this field is John Deere, a renowned manufacturer of construction and agricultural machinery. In their latest announcement, John Deere has introduced a groundbreaking development: advanced bucket teeth designed to revolutionize excavating operations.Bucket teeth are crucial components of an excavator's bucket, responsible for penetrating and excavating various materials with utmost precision. With a strong emphasis on durability, performance, and efficiency, John Deere has always been at the forefront of delivering cutting-edge solutions to construction and agricultural professionals. Now, they have taken their commitment to the next level with their new line of bucket teeth, engineered to redefine industry standards.One of the key features of John Deere's advanced bucket teeth is their groundbreaking design. Through extensive research and development, the company has created a tooth shape that combines enhanced cutting capabilities with maximum soil penetration. This not only boosts excavating efficiency but also minimizes wear and tear on both the teeth and the excavator itself. With these innovative teeth, construction and agricultural professionals can expect reduced excavation times, increased productivity, and substantial cost savings.In addition to their cutting-edge design, John Deere's new bucket teeth are manufactured using premium-grade materials. The company's relentless pursuit of quality ensures that every tooth is forged from hardened steel, rendering them exceptionally strong and resistant to wear. This durability translates to longer lifespan, significantly reducing the frequency of tooth replacements. By minimizing downtime and maximizing efficiency, John Deere's advanced bucket teeth prove to be a wise investment for any construction or agricultural venture.Safety has always been a top priority for John Deere, and their latest product line reflects this commitment. The new bucket teeth are designed with enhanced safety features, ensuring secure attachment to the bucket. The advanced locking mechanism provides a tight and reliable connection, preventing any accidental dislodgement during operations. This not only protects the operators but also safeguards the surrounding environment, reducing the risk of accidents and injuries on job sites.Moreover, John Deere's advanced bucket teeth are designed to be easily replaceable. Their user-friendly system allows for quick tooth replacement, minimizing downtime and maximizing productivity. This flexibility makes the teeth suitable for a variety of excavating tasks, from fine-grained soil to heavy rock formations. With the ability to switch teeth efficiently, construction and agricultural professionals can adapt to different terrains and conditions, completing their projects with utmost precision.John Deere's commitment to sustainability is also evident in their new bucket teeth. By reducing the need for frequent replacements, these teeth contribute to the overall longevity of excavating equipment, decreasing waste and promoting eco-friendly practices within the industry. Furthermore, the durability and efficiency of the teeth allow for optimized fuel consumption, minimizing environmental impact while maximizing returns for equipment owners.The introduction of John Deere's advanced bucket teeth has generated significant excitement within the construction and agricultural sectors. Construction companies and farmers alike recognize the potential of this innovation to revolutionize their operations. With improved cutting capabilities, exceptional durability, enhanced safety features, and simplified replacement process, John Deere's bucket teeth are set to become an industry benchmark.As the construction and agricultural industries continue to evolve, companies like John Deere play a critical role in driving innovation and meeting industry demands. With their latest breakthrough, John Deere has once again showcased their commitment to providing cutting-edge solutions that equip professionals with the tools they need to excel in their work. The advanced bucket teeth are a testament to the company's dedication to quality, productivity, and sustainability, empowering excavating professionals to achieve new levels of efficiency and success.

Enhance Efficiency with a High-Quality Excavator Grapple Bucket

article.Excavator Grapple Bucket Benefiting Industries Across the GlobeThe Excavator Grapple Bucket is a versatile piece of machinery that is being increasingly adopted by industries across the globe due to its ability to efficiently handle a variety of materials. Whether it is construction, forestry, or demolition, this bucket has been designed to provide an efficient and cost-effective solution.The Excavator Grapple Bucket is specifically designed to be mounted on the end of an excavator arm. With its powerful and robust structure, it can efficiently pick up, move, and dump materials such as scrap metal, debris, logs, and concrete. Its main feature is that it features two large grippers or jaws that can open and close to grasp the material. Once the material is held securely within the bucket, the excavator operator can move it to the desired location and release the material with precision, accuracy, and speed.One of the key advantages of the Excavator Grapple Bucket is its ability to handle and transport large and heavy materials with ease. Industries such as construction, mining, and demolition deal with massive quantities of materials that require efficient workflow management. This bucket can effortlessly handle materials such as boulders, rocks, and concrete debris, reducing the time, effort, and manual labor required to transport such heavy loads.Similarly, the forestry industry employs this bucket to handle logs and other heavy wood loads. The Excavator Grapple Bucket is designed for high load-bearing capacities and can handle even the heaviest logs. Coupled with high precision and efficient material handling, this bucket has transformed the forestry industry by reducing manual labor and increasing productivity.Additionally, the Excavator Grapple Bucket is often used in the waste management industry for handling and transporting waste. It can efficiently handle large quantities of garbage, construction debris and other types of waste materials. This bucket is particularly useful in landfills where it can easily pick up and transport waste to the designated dumping site.One of the significant advantages of this bucket is that it can be customized to suit specific industry needs. Different sizes, configurations, and features can be added to the bucket, making it adaptable to work in a variety of industrial environments. Accessories such as hydraulic thumbs, couplers and rotators can be added to the bucket to enhance its performance and flexibility.Excavator Grapple Buckets are available in both mechanical and hydraulic versions. Hydraulic versions have a better grip and control of the material being held within the bucket, making them more efficient and more widely used. The use of hydraulic technology means that the bucket can be controlled remotely from the excavator cab, ensuring safety and efficiency in the workplace.Several leading companies in the field of Excavator Grapple Bucket manufacturing have emerged. Their products are used by the construction, mining, forestry, and waste management industries across the globe. Their products are known for their robustness, durability, and customized features, making them ideal for use in industrial settings.One such manufacturer, {}, has been supplying high-quality Excavator Grapple Buckets to industries across the world. They have a range of products, including hydraulic and mechanical Excavator Grapple Buckets that suit different industries and applications. Their products are known for their reliability, durability, and customized designs that meet the specific needs of their clients.In conclusion, the Excavator Grapple Bucket is a versatile and efficient solution for handling large and heavy materials in industrial settings. Various industrial sectors such as construction, mining, forestry, and waste management have benefitted from the adoption of this bucket, resulting in increased productivity, reduced manual labor, and efficient workflow management. With further advancements in technology, Excavator Grapple Buckets are set to become more sophisticated, making them an indispensable tool for industries across the globe.

Durable Tooth Bar for Enhanced Performance: A Must-Have for Your Equipment

Excavating and digging are an essential part of many industries, from construction to agriculture. Ensuring that machinery is equipped with the right attachments and accessories is crucial for efficiency and effectiveness. That's where the Bolt On Tooth Bar comes in. This innovative tool is designed to enhance the performance of loaders and backhoes, providing them with increased digging and excavating capabilities.The Bolt On Tooth Bar is a rugged and durable attachment that is designed to easily bolt onto the cutting edge of a bucket, transforming it into a formidable digging tool. The teeth are made from high-quality steel and are designed to withstand the tough conditions and heavy-duty work that loaders and backhoes typically encounter. The tooth bar is available in various sizes to fit different bucket widths, and it can be easily installed without the need for any specialized tools or equipment.One of the key advantages of the Bolt On Tooth Bar is its ability to significantly increase the digging and excavating power of loaders and backhoes. The added teeth provide better penetration and grip into the ground, allowing for more efficient and productive digging. This means that operators can complete their work more quickly and with less effort, ultimately leading to cost savings and improved productivity.In addition to its digging capabilities, the Bolt On Tooth Bar also provides protection for the bucket's cutting edge, helping to extend its lifespan and reduce maintenance requirements. The tooth bar acts as a shield, absorbing the impact and wear from digging, and protecting the cutting edge from damage. This not only saves on repair and replacement costs but also reduces downtime and ensures that the loader or backhoe can continue to operate at peak performance.To showcase the benefits and features of the Bolt On Tooth Bar, we turn to {} - a leading provider of construction and agricultural machinery attachments and accessories. With a wide range of products designed to enhance the performance and versatility of heavy machinery, {} is dedicated to providing high-quality solutions for its customers.{} is known for its commitment to innovation and quality, and the Bolt On Tooth Bar is a testament to this. The company has developed this attachment with a focus on durability, reliability, and performance, ensuring that it meets the demands of the toughest working conditions. With a team of experienced engineers and designers, {} has created a product that not only meets industry standards but also exceeds customer expectations.Through extensive research and development, {} has optimized the design and construction of the Bolt On Tooth Bar to deliver maximum efficiency and effectiveness. The attachment is rigorously tested to ensure that it can withstand heavy use and challenging environments, providing operators with a tool they can rely on to get the job done.In addition to its commitment to quality, {} also values customer satisfaction and support. The company provides comprehensive customer service and technical support, ensuring that clients have access to the information and assistance they need to make the most of their Bolt On Tooth Bar. Whether it's installation guidance, maintenance advice, or troubleshooting support, {} is dedicated to helping its customers achieve the best results with their equipment.The Bolt On Tooth Bar from {} is a game-changer for loaders and backhoes, enhancing their digging and excavating capabilities and providing protection for their cutting edges. With a commitment to quality, innovation, and customer satisfaction, {} continues to be a leading provider of attachments and accessories for heavy machinery. Whether it's construction, agriculture, or any other industry that requires powerful digging tools, the Bolt On Tooth Bar is a solution that delivers results.

Essential Hardware: A Guide to Nuts, Bolts, and Washers

Nuts, Bolts, and Washers are essential components for many industries, and having a reliable supplier for these products is crucial for the success of any manufacturing business. One company that has been consistently providing top-quality nuts, bolts, and washers to its clients is {Company}. {Company} is a leading supplier of industrial fasteners, maintaining a strong presence in the market for several years. Their commitment to quality, reliability, and customer satisfaction has made them a preferred choice for many businesses across different industries. With a wide range of products and a dedication to meeting the needs of their clients, {Company} has built a solid reputation as a trusted supplier of nuts, bolts, and washers.In recent news, {Company} has announced the expansion of their product line to include a wider variety of nuts, bolts, and washers to better serve the needs of their customers. This expansion comes as a response to the growing demand for these essential components in various industries, including construction, automotive, aerospace, and manufacturing.The new product line includes a diverse range of nuts, such as hex nuts, lock nuts, wing nuts, and more, to accommodate different applications and requirements. In addition, {Company} has also expanded their selection of bolts, offering different types and sizes to meet the specific needs of their customers. With the inclusion of various washers, such as flat washers, lock washers, and other specialty washers, {Company} aims to provide a comprehensive range of fasteners to their clients.One of the key factors that set {Company} apart from other suppliers is their commitment to quality. All of their products undergo stringent quality control measures to ensure that they meet the highest industry standards. By adhering to strict quality guidelines, {Company} guarantees that their nuts, bolts, and washers are reliable, durable, and capable of withstanding the demands of various industrial applications.Apart from the quality of their products, {Company} also prides itself on its exceptional customer service. Their team of knowledgeable and experienced professionals is dedicated to assisting their clients in finding the right fastening solutions for their specific needs. Whether it's providing technical guidance or offering personalized recommendations, {Company} goes above and beyond to ensure that their customers receive the support they need.Moreover, {Company} understands the importance of timely delivery, and they have established efficient logistics and distribution channels to ensure that their products reach their customers on time. This commitment to reliability and efficiency has earned {Company} the trust and loyalty of many businesses that rely on their products to keep their operations running smoothly.As {Company} continues to expand its product line and enhance its services, they remain focused on their core values of quality, reliability, and customer satisfaction. Their dedication to exceeding the expectations of their clients has positioned them as a leading supplier of nuts, bolts, and washers in the industry.In conclusion, the expansion of {Company}'s product line to include a wider variety of nuts, bolts, and washers is a testament to their commitment to meeting the evolving needs of their customers. With a focus on quality, reliability, and exceptional customer service, {Company} is well-equipped to continue serving the fastening needs of various industries and maintaining its position as a trusted supplier of industrial fasteners.

An Overview of Vital Excavator Parts You Should Know

Title: Innovative Excavator Part Revolutionizes Construction IndustryIntroduction:Innovation is at the heart of every industry, and the construction sector is no exception. As technology continues to advance, companies are constantly striving to find new and improved solutions to increase efficiency and productivity. One such innovation in the excavator industry has brought about a significant breakthrough, promising to revolutionize the way construction projects are carried out. This groundbreaking development comes from a leading company, known for its expertise in manufacturing excavator equipment, including the latest excavator part that has dominating the market.Background:The construction industry heavily relies on excavators for various tasks, including digging, lifting, and moving heavy materials. It is crucial for these machines to have reliable and durable parts to ensure the smooth operation of projects. In light of this, the reputable company has introduced a revolutionary new excavator part that guarantees enhanced performance, unrivaled durability, and heightened efficiency.Key Features and Technology:The newly developed excavator part incorporates state-of-the-art technologies, which have been meticulously engineered to address the industry's pain points and improve overall productivity. These innovative features include:1. Advanced Material Composition: The excavator part is constructed using a proprietary blend of durable and lightweight materials, resulting in increased strength and decreased operating weight. This unique composition allows for improved fuel efficiency and reduced environmental impact.2. Precision Engineering: The part undergoes rigorous design and engineering processes, leveraging groundbreaking techniques to optimize its performance. The intricate design enhances the part's maneuverability, allowing for precise movements and enhanced control during operation.3. Cutting-Edge Technology Integration: The part seamlessly integrates with the excavator's existing systems, leveraging advanced sensors and electronics. Real-time data collection empowers operators with crucial information about the machine's performance, enabling prompt adjustments and minimizing downtime.Benefits and Impacts:The introduction of this innovative excavator part presents several far-reaching benefits and impacts on the construction industry:1. Enhanced Efficiency: The improved design and technology of the excavator parts translate to increased productivity and faster completion of construction projects. The precision engineering allows for more precise movements, reducing the need for costly rework.2. Cost Savings: The advanced fuel efficiency, reduced maintenance requirements, and extended lifespan of the excavator part result in significant cost savings for construction companies. The decreased fuel consumption and fewer repairs contribute to a healthier bottom line.3. Environmental Friendliness: The excavation process can have a negative impact on the environment through fuel emissions and inefficient resource utilization. The new excavator part's lightweight composition and fuel-saving capabilities reduce the sector's carbon footprint, making construction projects more eco-friendly.4. Operator Safety and Comfort: The integration of cutting-edge technology into the excavator part contributes to operator safety and comfort. Real-time data collection helps identify potential hazards, allowing operators to take preventive measures. Additionally, improved maneuverability and reduced vibration enhance the operator's overall experience, reducing fatigue and increasing alertness.Conclusion:The development of this revolutionary excavator part is set to shape the future of the construction industry. With its exceptional performance, durability, and the incorporation of cutting-edge technology, construction companies can expect improved efficiency, cost savings, and reduced environmental impact. As this innovative part gains popularity and market dominance, it solidifies the company's position as a leader in the excavator equipment manufacturing industry, driving the sector towards a more efficient and sustainable future.